Common Issues Regarding Back Pressure Regulator Selection and Performance

In the evolving landscape of fluid control systems, the selection and performance of back pressure regulators have become critical considerations for engineers and operators alike. As we navigate the complexities of system designs and operational efficiencies, understanding the common issues associated with back pressure regulators is essential to optimize their performance and reliability.

With various factors influencing their functionality, ranging from the types of media handled to the specific application requirements, it is imperative to address potential challenges that could arise during the selection process. This blog aims to explore these common issues and provide insights into the future of back pressure regulators, helping professionals make informed decisions that enhance operational effectiveness and ensure the longevity of their systems.

Key Factors in Selecting the Right Back Pressure Regulator for Your System

When selecting a back pressure regulator for your system, several key factors must be considered to ensure optimal performance. First and foremost, understanding the specific pressure requirements of your application is crucial. The regulator’s set pressure needs to align perfectly with your system's operational parameters, ensuring stable pressure control. Additionally, consider the fluid characteristics, including viscosity and temperature, as these can significantly influence the selection process.

Tip: Always consult the manufacturer's specifications and performance curves, as they provide valuable insights into how the regulator will behave under different operational conditions.

Another important aspect is the regulator's response time and flow capacity. A regulator with an adequate flow rate prevents fluctuations that could disrupt processes or equipment. Ensure that any potential pressure drop across the device does not adversely affect your application.

Tip: Conducting a thorough analysis of your system's flow requirements can help you avoid common pitfalls associated with selecting a regulator that does not meet your needs.

Lastly, consider the materials of construction, particularly when dealing with corrosive or abrasive fluids. Selecting the appropriate materials can enhance the longevity and reliability of the regulator.

Tip: Always prioritize compatibility with the media being regulated to prevent premature failure and ensure consistent performance over time.

Common Performance Issues and Troubleshooting Tips for Back Pressure Regulators

When selecting a back pressure regulator, understanding common performance issues is crucial for maintaining system efficiency. One prevalent problem is drift in pressure settings, which can arise from fluctuations in flow rates or temperature changes. To troubleshoot this, ensure that the regulator is properly sized for the application and check for any possible blockages in the upstream or downstream lines that may affect the flow. Additionally, employing a regulator with a suitable diaphragm material can help mitigate issues related to chemical compatibility, preventing material degradation and performance inconsistencies.

Another significant concern is the regulator's response time to pressure changes. Slow response can lead to process instability, especially in dynamic systems. To enhance response, consider using regulators designed for rapid adjustments and ensure that the installation minimizes dead space in the piping. Regular maintenance, such as cleaning the regulator and inspecting seals, is essential to ensure peak performance. Monitoring pressure performance during operation can also help identify potential problems before they escalate, allowing for proactive intervention and sustained efficiency in the system.

Common Issues Regarding Back Pressure Regulator Selection and Performance

| Issue | Description | Symptoms | Troubleshooting Tips |

|---|---|---|---|

| Incorrect Sizing | Regulator is not adequately sized for the application. | Fluctuating pressure, frequent adjustments needed. | Re-evaluate system requirements and select a better match for flow rates. |

| Material Compatibility | Material of the regulator is not compatible with the fluid. | Corrosion, leaking, or premature failure. | Check fluid properties and choose materials that provide better resistance. |

| Pressure Instability | Regulator shows erratic pressure readings. | Inconsistent flow, system pressure spikes or dips. | Verify the installation, assess the inlet and outlet conditions. |

| Dirty or Clogged Filters | Filters upstream of the regulator are not maintained. | Reduced flow, increased back pressure. | Regularly inspect and clean or replace filters as necessary. |

| Temperature Extremes | Operating outside the recommended temperature range. | Sticking parts, damage to seals or diaphragms. | Ensure proper thermal management and select regulators rated for the temperature. |

Understanding the Impact of Pressure Settings on Regulator Efficiency

Pressure settings play a crucial role in the efficiency of back pressure regulators (BPRs). When a regulator is set to an inappropriate pressure level, it can lead to a variety of performance issues, including unstable flow rates and reduced system efficiency. According to a report by the National Institute of Standards and Technology, optimizing pressure settings can improve energy utilization by up to 20% in certain industrial applications. This highlights the importance of accurately determining the desired pressure levels based on system requirements and the characteristics of the fluid being regulated.

Additionally, the impact of pressure settings on regulator efficiency is compounded by variations in fluid properties, temperature, and upstream pressure fluctuations. A study published in the Journal of Fluid Mechanics indicates that even slight deviations from the optimal pressure setting can result in losses of up to 15% in flow efficiency. This underscores the need for regular calibration and maintenance of back pressure regulators to ensure they are operating within the specified pressure ranges. Overall, understanding and managing pressure settings effectively can lead to significant improvements in system performance and operational costs.

Common Issues Regarding Back Pressure Regulator Selection and Performance

Maintenance Best Practices to Ensure Optimal Back Pressure Regulator Functionality

When it comes to the maintenance of back pressure regulators, following best practices is crucial to ensure optimal functionality. Regular inspections are essential to identify any wear and tear that could affect performance. It’s advisable to check the regulator for leaks, corrosion, and any signs of failure. Keeping the regulator clean and free from debris will also enhance its efficiency and lifespan.

Tips: Implementing a routine maintenance schedule can significantly mitigate issues. Consider utilizing pressure gauges to monitor performance and detect any deviations from normal operation. Additionally, training your team on proper handling techniques will help preserve the integrity of the equipment.

Periodic testing of the back pressure regulator is another vital practice. This includes evaluating the set pressure and ensuring that it aligns with system requirements. Adjustments may be necessary over time, so regular calibration helps maintain accuracy. It's also beneficial to document maintenance actions for future reference, fostering a proactive approach to managing system integrity.

Comparative Analysis of Different Back Pressure Regulator Types and Their Applications

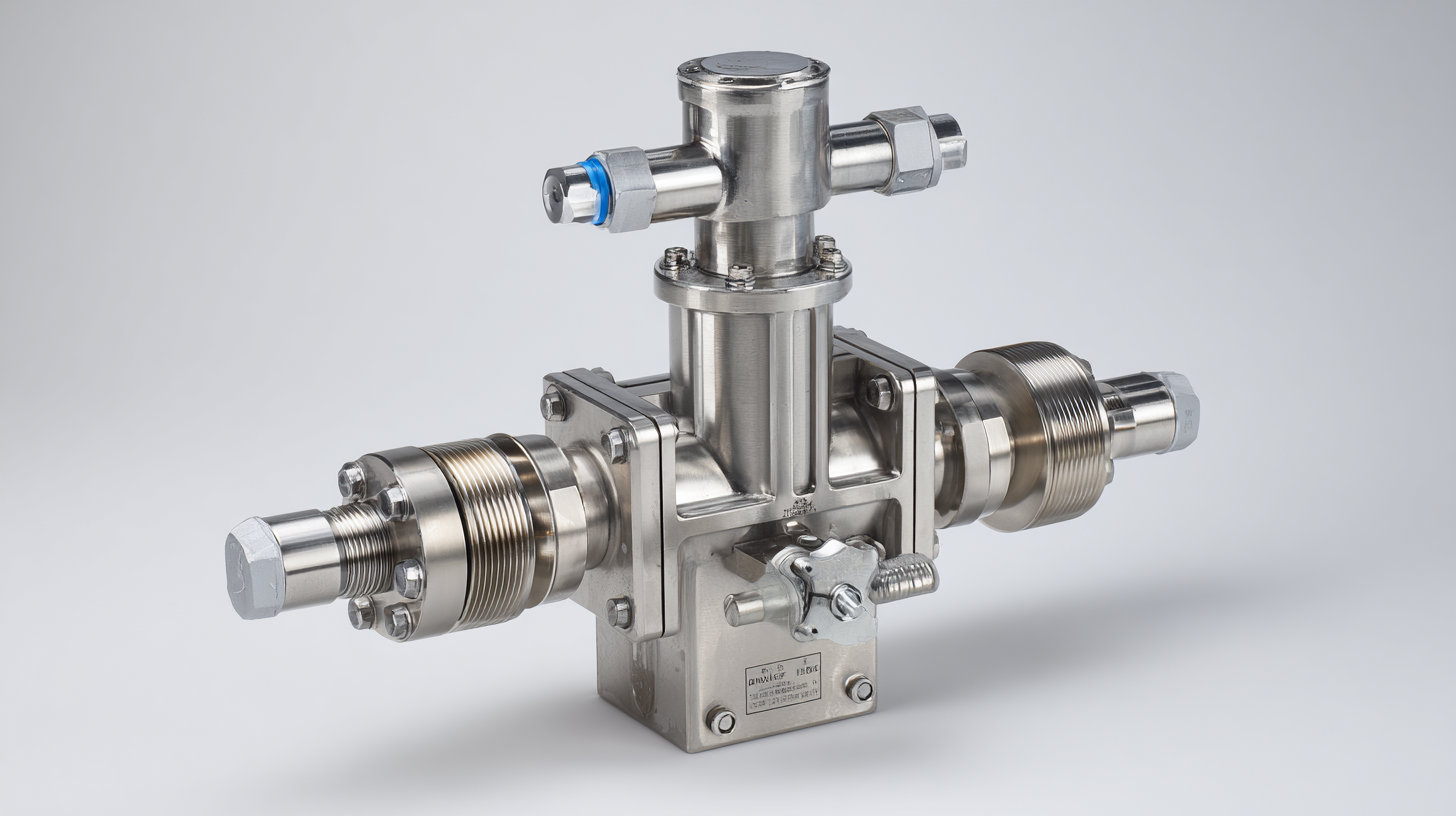

When selecting a back pressure regulator, it is essential to consider the specific application and the type of regulator that best suits your needs. There are several types of back pressure regulators available, each offering distinct advantages and functionalities. For instance, spring-loaded regulators are commonly used for their simplicity and reliability, making them ideal for applications with relatively stable flows. In contrast, volumetric or electronically controlled regulators provide greater precision and can adapt to varying flow conditions, making them suitable for more complex systems where consistent pressure is critical.

Furthermore, the choice of material and construction can significantly influence the performance of a back pressure regulator. Factors such as temperature, pressure rating, and the chemical compatibility of the materials with the process fluid need to be evaluated. For example, regulators made from stainless steel may be preferred in corrosive environments, while those with elastomer seals may be better suited for applications involving gases. By conducting a comparative analysis of these regulator types and their applications, engineers can make informed decisions, ensuring optimal performance and longevity in their systems.