2025 How to Choose the Right Temperature Control Valve for Your Needs

Choosing the right temperature control valve is crucial for ensuring optimal performance and efficiency in various applications, from industrial processes to HVAC systems. As John Smith, a renowned expert in the temperature control valve industry, aptly puts it, "The effectiveness of a system often hinges on selecting the appropriate valve to maintain desired temperature settings." The right valve not only influences the temperature regulation but also plays a significant role in energy conservation and cost reduction.

In today’s rapidly evolving technological landscape, understanding the specifications and functionalities of temperature control valves is more important than ever. Different applications demand different performance characteristics, which can make choosing the right valve a daunting task. Factors such as valve size, type, and the medium being controlled must be carefully considered to ensure that the selected valve operates seamlessly within the intended system. As we delve into the intricacies of temperature control valves, this guide aims to provide clarity and guidance, helping you make informed decisions tailored to your specific needs while maximizing efficiency and reliability.

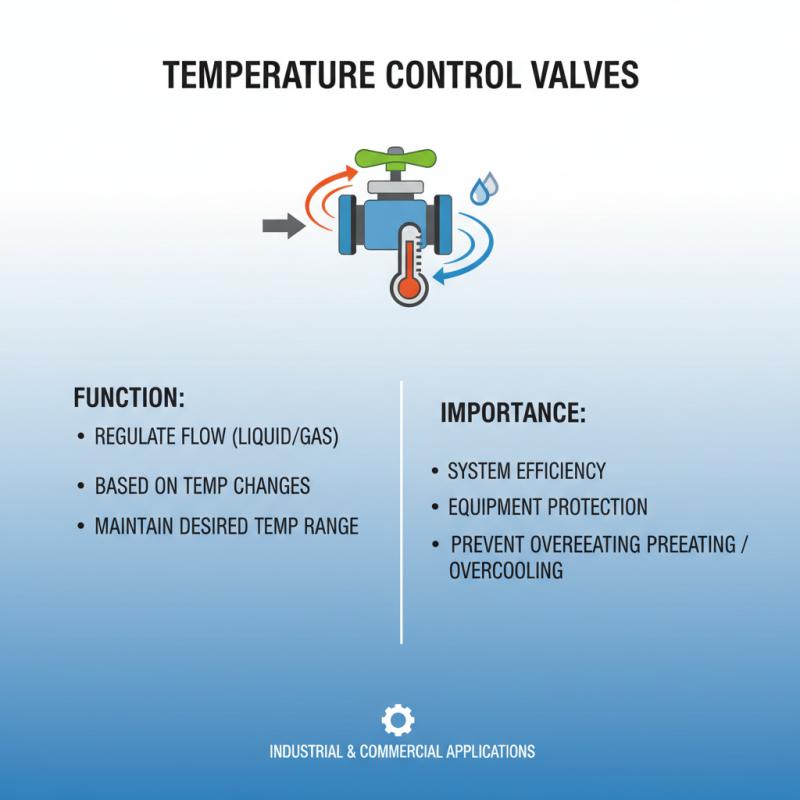

Understanding the Basics of Temperature Control Valves

Temperature control valves play a crucial role in various industrial and commercial applications, ensuring that systems operate efficiently and safely. Understanding these valves begins with their basic function: they regulate the flow of liquid or gas based on temperature changes. This ensures that the desired temperature is maintained within a specific range, protecting both equipment and processes from the potential damage that can occur from overheating or excessive cooling.

When selecting a temperature control valve, it’s essential to consider factors such as the type of medium being controlled, the required temperature range, and the valve's compatibility with existing systems. Additionally, you should evaluate the valve's response time, as well as its maintenance needs, to ensure long-term reliability and performance.

**Tips for Choosing the Right Temperature Control Valve:**

- Always determine the exact specifications required for your application before making a selection.

- Consult with experts or refer to technical resources to match the valve type with the medium it will be controlling.

- Consider the installation environment, including space constraints and accessibility for future maintenance.

Identifying Your Specific Temperature Control Needs

When it comes to selecting the right temperature control valve, understanding your specific needs is paramount. Various industries require precise temperature management, and failing to identify the unique parameters can lead to inefficiencies and increased operational costs. According to the International Society of Automation, nearly 30% of industrial processes suffer from improper temperature control, leading to diminished product quality and increased energy consumption. By clearly defining your operational temperature ranges, flow demands, and specific application environments, you can enhance system performance and reliability.

Tips for identifying your temperature control needs include analyzing your process requirements in detail. Begin by evaluating the desired temperature range and the acceptable tolerances within your operations. This assessment should also encompass factors such as fluid characteristics, pressure levels, and the potential for fluctuations in demand. A report from the Association of Energy Engineers highlights that temperature control optimization can result in energy savings of up to 25%, making the initial analysis not only prudent but also financially beneficial.

In addition, consider the environmental conditions where the valve will be installed. Factors such as ambient temperature, humidity, and exposure to chemicals can all affect the valve's performance. By selecting a valve that is specifically designed to withstand your operational environment, you can extend its lifespan and reduce maintenance costs. Remember that thorough research and a clear understanding of your specific temperature control needs are essential steps toward making an informed decision for your system's efficiency and reliability.

2025: How to Choose the Right Temperature Control Valve for Your Needs

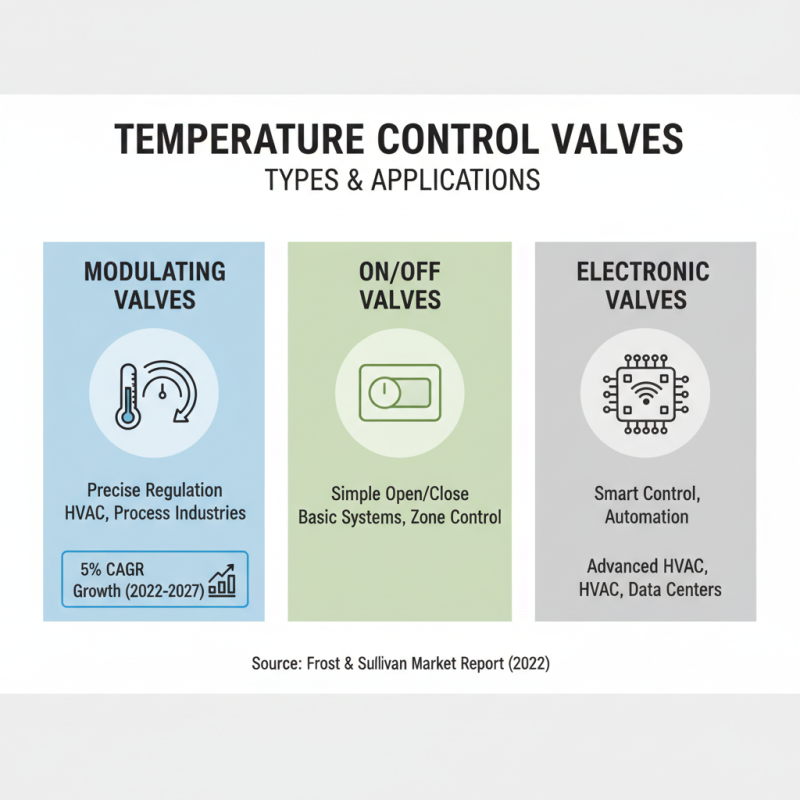

Types of Temperature Control Valves and Their Applications

When choosing a temperature control valve, it is essential to understand the various types available and their specific applications. Temperature control valves can be broadly categorized into three main types: modulating valves, on/off valves, and electronic valves. Modulating valves offer precise temperature regulation by allowing for gradual adjustments, making them suitable for applications in HVAC systems and process industries where maintaining a specific temperature setpoint is crucial. According to a recent market report by Frost & Sullivan, the demand for modulating valves is projected to grow at a compound annual growth rate (CAGR) of 5% from 2022 to 2027, emphasizing their importance in both industrial and commercial settings.

On the other hand, on/off valves are designed for simple operation, providing complete closure or full flow, which is ideal for applications requiring an "all or nothing" approach. These valves are commonly used in hot water systems and heating applications due to their straightforward functionality and lower costs. Additionally, electronic temperature control valves, which utilize smart technology and IoT capabilities, are gaining traction within the industry. They enable remote monitoring and precise control through sophisticated algorithms. According to a recent report from Global Industry Analysts, the electronic valve market is expected to exceed $4 billion by 2025, driven by advancements in smart technologies and increased automation in industrial processes.

Understanding the application environments and specific needs of your operations will help you select the right type of temperature control valve. Each type has distinct advantages and is tailored to different operational demands, from precision and automation to simplicity and cost-effectiveness.

Key Features to Consider When Selecting a Valve

When selecting the right temperature control valve, there are several key features you should consider to ensure optimal performance for your specific application. First, evaluate the valve's material compatibility. The construction material needs to withstand the temperature and pressure of the medium it will control. Common materials include stainless steel and brass, each suited for different environments.

Another essential factor is the valve's actuating mechanism. Choose between manual, electric, or pneumatic actuation based on your operational needs. Electric actuators, for instance, provide precision and remote control capabilities, while manual options might be more suitable for simpler applications.

Additionally, assess the flow characteristics of the valve, such as modulating or on/off control, to match the specific requirements of your system.

Tips: Always review the pressure drop across the valve as it affects the overall system efficiency. Ensure to factor in maintenance ease when selecting the valve; designs that allow for easy access to internal components can significantly reduce downtime. Lastly, consult with professionals or technical manuals when in doubt about the specifications to ensure the best match for your operational needs.

Best Practices for Installation and Maintenance of Temperature Valves

When it comes to installing and maintaining temperature control valves, following best practices is crucial for ensuring optimal performance and longevity. Proper installation begins with selecting the right location for the valve. It should be positioned in a way that allows for easy access for maintenance while also being strategically placed to achieve accurate temperature readings. Make sure to adhere to manufacturer guidelines regarding piping orientation and ensure there are no obstructions that could affect the valve’s operation. Additionally, using proper sealing and connection techniques will prevent leaks and enhance the reliability of the system.

Maintenance of temperature valves involves regular inspection and adjustment to ensure they function efficiently. Routine checks should include examining the valve for any signs of wear, corrosion, or blockage. Cleaning the valve periodically can prevent debris buildup, which may impede performance. It’s also important to test the valve’s response to temperature changes; if it does not operate correctly, recalibrating or replacing the valve may be necessary. Keeping detailed records of maintenance activities can help in identifying potential issues early and prolong the service life of your temperature control system.

2025 How to Choose the Right Temperature Control Valve for Your Needs - Best Practices for Installation and Maintenance of Temperature Valves

| Feature | Importance | Best Practice |

|---|---|---|

| Temperature Range | Ensures valve operates within desired limits | Select valves rated for your specific range |

| Material Compatibility | Prevents corrosion and contamination | Choose materials that match the process fluid |

| Size and Flow Rate | Affects pressure drop and system efficiency | Use flow calculations to determine needed size |

| Control Method | Influences response time and accuracy | Select between pneumatic, electric, or hydraulic controls |

| Maintenance Requirements | Ensures long-term reliability and performance | Schedule regular inspections and servicing |

| Installation Location | Impacts heat transfer efficiency | Install in the optimal position for performance |

| Type of Application | Determines the required features and performance | Identify application-specific needs before selection |

Related Posts

-

Innovative Solutions for Effective Temperature Control Valve Integration

-

Understanding the Functionality of the Best Back Pressure Valve

-

8 Proven Best Practices for Optimizing Natural Gas Regulators Performance

-

The Ultimate Guide to Choosing the Right Gas Pressure Regulator for Optimal System Performance

-

The Future of Precision Control: Innovations in Flow Regulator Technology

-

Innovative Alternatives in High Pressure Gas Regulators for 2025 Technological Advancements