How to Choose the Best Gas Regulator Valve for Optimal Safety and Performance in Industrial Applications

In the industrial sector, the importance of selecting the right gas regulator valve cannot be overstated, as it plays a crucial role in ensuring both safety and performance in various applications. According to a recent report by MarketsandMarkets, the global gas regulator market is expected to reach USD 5.48 billion by 2026, growing at a CAGR of 5.6% from 2021 to 2026. This growth underscores the increasing reliance on gas-regulated processes across industries, from manufacturing to energy production. A well-chosen gas regulator valve not only enhances operational efficiency but also significantly mitigates the risks associated with gas handling, which can lead to catastrophic failures if improperly managed. Therefore, understanding the critical factors for selecting an optimal gas regulator valve is essential for industries aiming to maintain stringent safety standards while maximizing performance.

Key Factors to Consider When Selecting a Gas Regulator Valve for Industrial Use

When selecting a gas regulator valve for industrial applications, several key factors must be taken into account to ensure optimal safety and performance. First, consider the type of gas being regulated, as different gases have varying properties and requirements. For instance, a regulator designed for natural gas may not be suitable for corrosive gases like ammonia. Always verify compatibility with the specific gas to avoid hazardous situations.

Another important aspect is the pressure rating and flow capacity of the valve. It should be sufficient to handle the maximum expected pressure and flow rate in your application. Oversized or undersized regulators can lead to inefficient operation or even equipment failure. It’s advisable to consult product specifications and, if necessary, seek advice from professionals in the field.

**Tip:** Regular maintenance and inspection of the regulator valve are essential. Over time, wear and tear can compromise its functionality, posing safety risks. Schedule routine checks to ensure everything is operating within safe parameters. Additionally, consider the installation location; avoid areas prone to extreme conditions that may affect the regulator’s performance.

Gas Regulator Valve Selection Factors

Understanding Different Types of Gas Regulator Valves and Their Applications

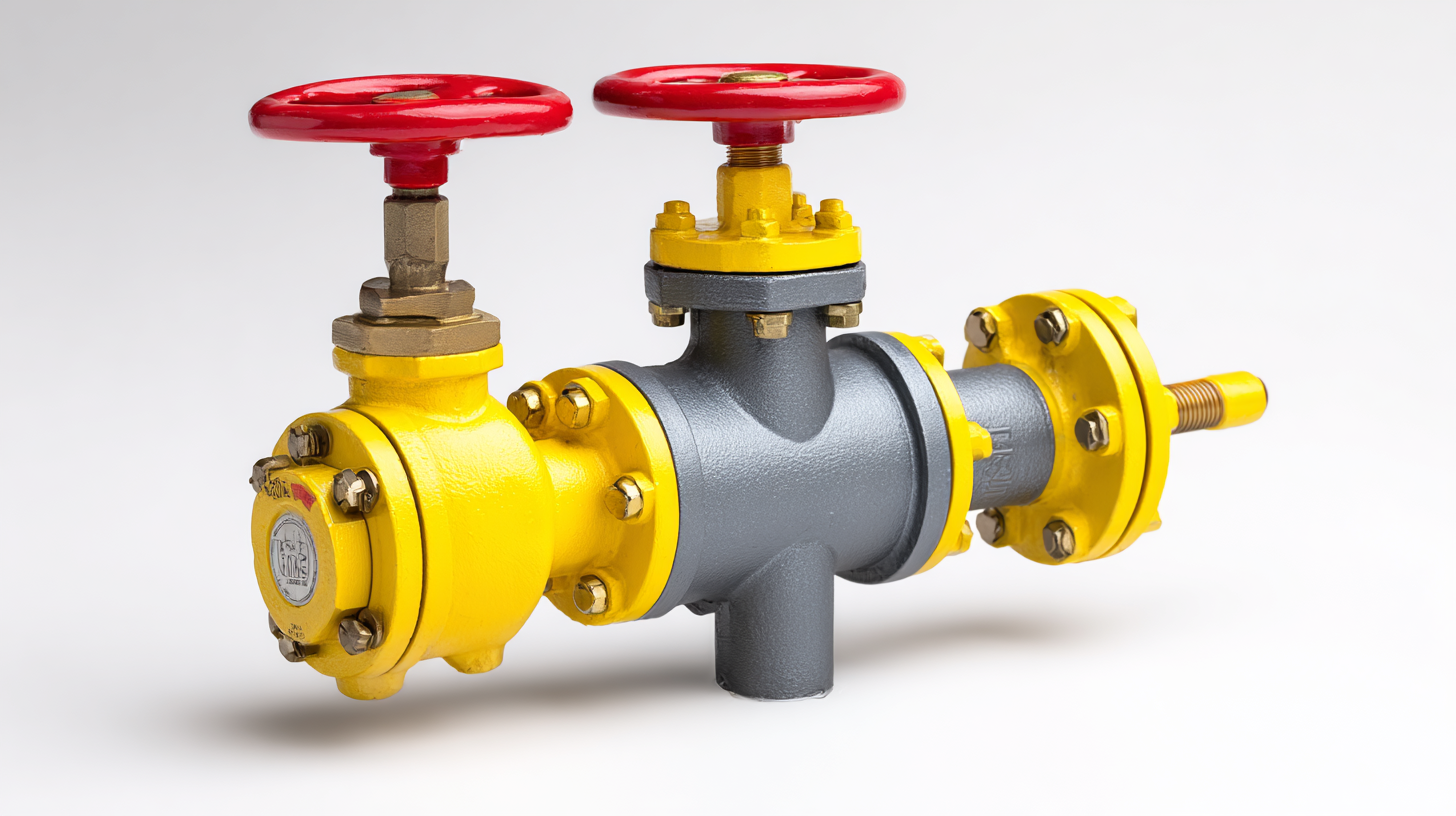

When selecting a gas regulator valve for industrial applications, understanding the various types and their specific applications is essential for ensuring optimal safety and performance. Gas regulators can primarily be classified into two categories: pressure reducing regulators and back pressure regulators. Pressure reducing regulators maintain downstream pressure within a desired range, ensuring consistent delivery of gas for processes such as welding and heating. According to a report by MarketsandMarkets, the global gas regulator market is expected to grow at a CAGR of 5.4% from 2021 to 2026, driven by the increasing demand for energy-efficient solutions.

In addition to functionality, it’s crucial to consider the materials and design of the gas regulator valve. For instance, stainless steel regulators are often preferred for corrosive environments due to their durability and resistance to oxidation. Furthermore, the gas type being regulated—whether natural gas, propane, or industrial gases like nitrogen—will dictate the specific design and sealing requirements. The American National Standards Institute (ANSI) emphasizes that proper selection and installation of gas regulators are vital in preventing mishaps associated with improper gas flow, underscoring the critical link between design specifics and safety outcomes in industrial settings.

Safety Features to Look for in a High-Performance Gas Regulator Valve

When selecting a gas regulator valve for industrial use, prioritizing safety features is crucial to ensure optimal performance and mitigate risks. According to the Occupational Safety and Health Administration (OSHA), improper gas regulation can lead to explosions, equipment failures, and hazardous leaks, emphasizing the need for reliable safety mechanisms. High-performance gas regulator valves should include over-pressure protection, which prevents excessive pressure build-up that could result in catastrophic failures. Additionally, look for valves with built-in emergency shut-off capabilities, allowing for immediate cessation of gas flow during hazardous situations.

Tip: Always verify that the gas regulator valve complies with industry standards, such as those set by the American National Standards Institute (ANSI) or the National Fire Protection Association (NFPA). This not only assures compliance but also enhances safety protocols within your operations.

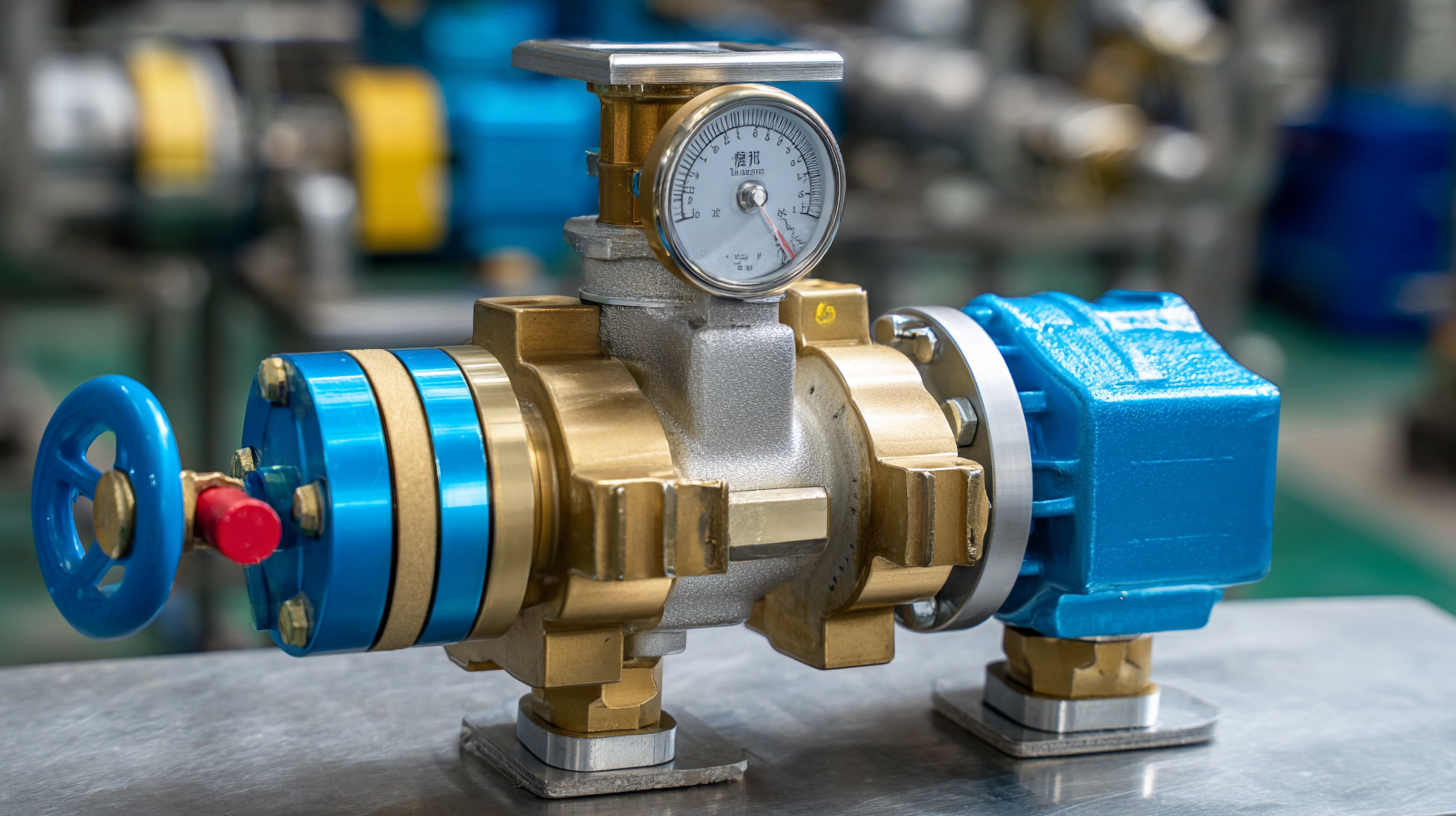

Consider also the material and construction of the valve. Regulators made from durable materials like stainless steel can withstand high pressures and corrosive environments, which is critical in many industrial settings. Incorporating features like a gauge for pressure monitoring can provide real-time data that aids in proactive maintenance and safety management.

Tip: Regularly inspect and test your gas regulator valves to ensure they function properly and meet safety standards. Implementing a routine maintenance schedule can significantly reduce the risk of unexpected failures.

Common Mistakes in Gas Regulator Valve Selection and How to Avoid Them

Selecting the right gas regulator valve is crucial for ensuring safety and optimal performance in industrial applications. However, many professionals fall into common pitfalls that can jeopardize both efficiency and safety. One prevalent mistake is underestimating the importance of compatibility with specific gas types. Each gas has unique properties requiring corresponding regulator specifications. Always verify that the regulator is designed to handle the precise gas being used, as mismatches can lead to hazardous situations.

Another frequent oversight revolves around the pressure rating of the regulator. Users often choose regulators based on initial requirements without considering potential future demands. A regulator that cannot accommodate fluctuating pressures may fail, causing equipment damage or an unsafe environment. It’s essential to select a regulator with a suitable pressure range that not only meets current specifications but can also handle future growth or unexpected demands. Prioritizing these elements can greatly enhance the safety and reliability of industrial gas systems.

How to Choose the Best Gas Regulator Valve for Optimal Safety and Performance in Industrial Applications

| Selection Criteria | Common Mistakes | Optimal Choices |

|---|---|---|

| Pressure Rating | Ignoring the operational pressure requirements. | Select a regulator rated for higher than the maximum operational pressure. |

| Type of Gas | Using a regulator designed for a different type of gas. | Ensure compatibility with the specific gas type being used. |

| Flow Rate | Selecting a valve that does not meet the flow requirements. | Match the regulator flow rate with the application needs. |

| Material Compatibility | Using a regulator with incompatible materials. | Choose materials that are compatible with the gas and environmental conditions. |

| Installation and Maintenance | Neglecting proper installation and maintenance procedures. | Follow manufacturer guidelines for installation and routine checks. |

The Role of Compliance Standards in Choosing Gas Regulator Valves for Industries

Choosing the right gas regulator valve for industrial applications is crucial, not only for optimal performance but also for compliance with industry regulations. As various sectors, including shipping and the chemical industry, prepare for increasing regulatory scrutiny, understanding the role of compliance standards is more important than ever. Regulations such as Regulation 2016/426 set forth essential requirements for the design and manufacture of gas appliances, and adhering to these standards can mean the difference between operational success and costly penalties.

Tip: Always verify that your gas regulator valves are compliant with the latest regulations relevant to your industry. This may include familiarizing yourself with pressure equipment safety standards to ensure that all components meet legal requirements before installation.

Moreover, considering the recent warnings about non-compliant gas regulators underlines the importance of using the right equipment. The push towards sustainability and reducing emissions in the oil and gas sector emphasizes the need for reliable, compliant equipment that minimizes leaks and maximizes efficiency.

Tip: Regularly consult regulatory updates and participate in industry consultations to stay informed about any changes that may impact your operations. This proactive approach will not only help in maintaining compliance but also enhance the safety and performance of your gas regulation systems.