5 Essential Tips for Choosing the Best Hydrogen Pressure Regulator

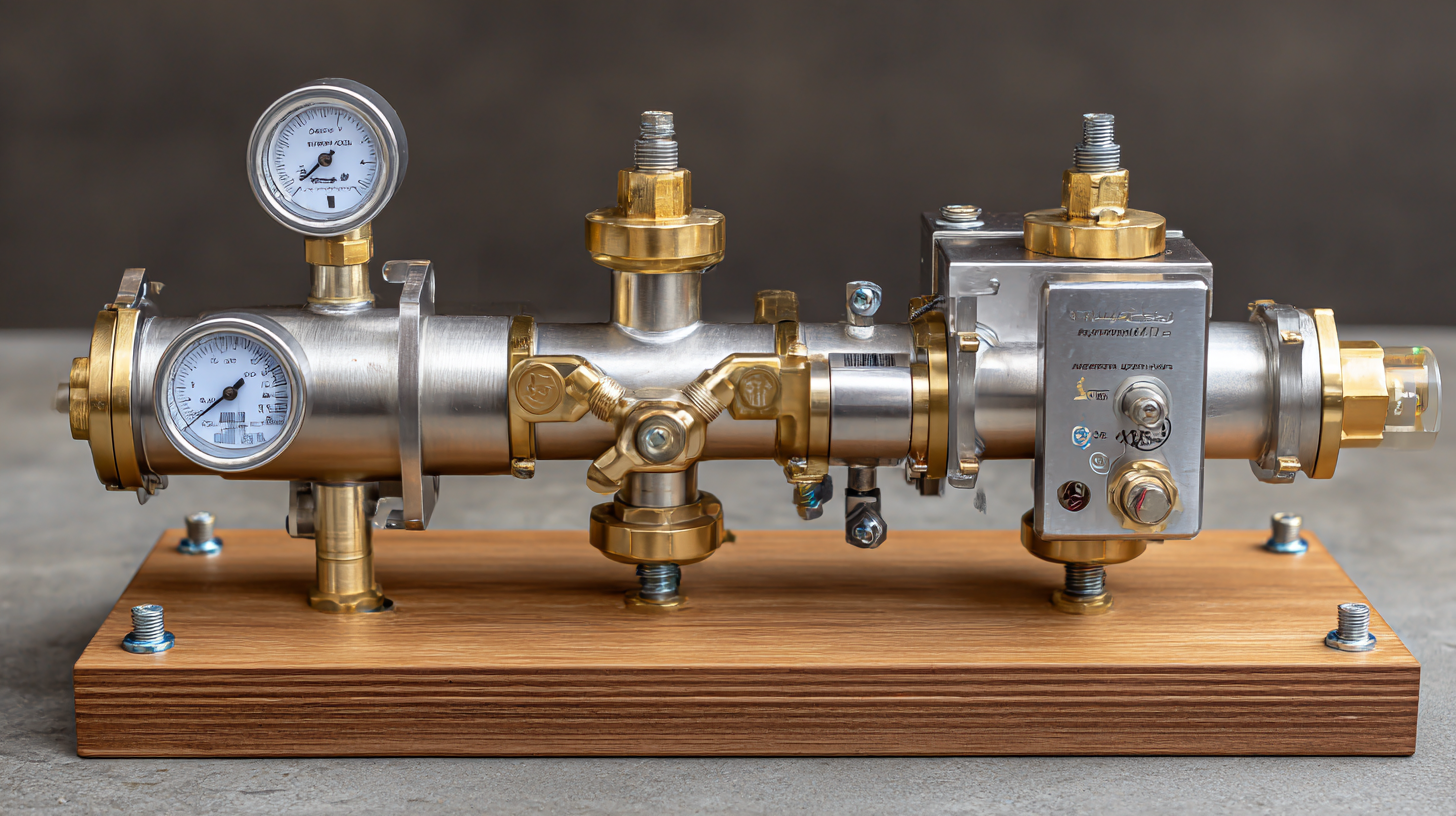

When working with hydrogen systems, one of the critical components to consider is the hydrogen pressure regulator. Choosing the right regulator can significantly influence the efficiency, safety, and performance of your hydrogen applications. With the growing use of hydrogen in various industries, from energy production to fuel cell technology, understanding the key factors behind selecting a suitable hydrogen pressure regulator is essential.

This blog will provide you with five essential tips that will guide you through the decision-making process, ensuring that you select a regulator that meets your specific needs. Whether you are a beginner or have experience in handling hydrogen systems, these top strategies will help you navigate the complexities of pressure regulation, ultimately enhancing the effectiveness and safety of your operations.

Key Factors to Consider When Selecting a Hydrogen Pressure Regulator

When selecting a hydrogen pressure regulator, there are several key factors to consider to ensure optimal performance and safety. Firstly, it is crucial to evaluate the flow rate requirements of your application. Different systems demand varying flow rates, so understanding your specific needs will help you choose a regulator that can efficiently handle the required capacity without any pressure drop or inefficiencies.

When selecting a hydrogen pressure regulator, there are several key factors to consider to ensure optimal performance and safety. Firstly, it is crucial to evaluate the flow rate requirements of your application. Different systems demand varying flow rates, so understanding your specific needs will help you choose a regulator that can efficiently handle the required capacity without any pressure drop or inefficiencies.

Another important consideration is the pressure range the regulator can handle. Hydrogen applications often require specific pressure outputs, and selecting a regulator that accommodates your desired pressure range will help maintain consistent performance. Additionally, check the regulator’s materials and construction; they should be compatible with hydrogen gas to avoid potential leaks or degradation. Lastly, ensure that the regulator meets relevant safety standards and certifications, as this will provide peace of mind regarding its reliability in demanding environments.

Understanding Different Types of Hydrogen Pressure Regulators Available

When it comes to selecting the right hydrogen pressure regulator, understanding the different types available is crucial. Hydrogen pressure regulators generally fall into two main categories: single-stage and multi-stage regulators. Single-stage regulators are typically more straightforward and ideal for applications that require a quick response and low pressure variation. These are often used in laboratories and research environments where precise control is less critical. On the other hand, multi-stage regulators offer improved pressure stability and are suited for industrial applications where hydrogen is used as a fuel source or in chemical processes. They manage higher pressure variations and provide a more consistent output.

In addition to single and multi-stage regulators, it's essential to consider diaphragm and piston types. Diaphragm regulators are favored for their sensitivity and precise control, making them suitable for applications that demand accurate pressure management. Conversely, piston regulators can handle higher flow rates and are more durable, making them ideal for heavy-duty industrial use. Each type of regulator comes with its own set of advantages and considerations, so understanding these differences enables users to make informed decisions tailored to their specific hydrogen application needs.

Evaluating Pressure and Flow Rate Requirements for Your Application

When selecting a hydrogen pressure regulator, evaluating pressure and flow rate requirements is crucial for optimizing performance in your specific application. According to a recent report by the Hydrogen and Fuel Cell Technical Advisory Committee (HFTAC), the efficiency of hydrogen systems can be significantly impacted by improperly matched regulators. For instance, if the regulator does not accommodate the necessary pressure range, it may lead to operational inefficiencies or safety hazards. It is essential to determine the maximum inlet pressure and the desired outlet pressure for your system to ensure you select a regulator that meets these specifications.

Moreover, flow rate requirements vary widely based on the application, whether it’s for industrial processes or fuel cells. The U.S. Department of Energy (DOE) has indicated that effective flow rates can range from 0.2 to 20 liters per minute, emphasizing the need to assess the specific demands of your process. A regulator that can handle the expected flow variations not only promotes system efficiency but also prolongs the lifespan of the components involved. Therefore, conducting thorough research on your application’s unique pressure and flow requirements before choosing a hydrogen pressure regulator is vital to achieving reliable operation and maximizing productivity.

5 Essential Tips for Choosing the Best Hydrogen Pressure Regulator - Evaluating Pressure and Flow Rate Requirements for Your Application

| Pressure Range (psi) | Flow Rate (scfh) | Material | Port Size (inches) | Weight (lbs) |

|---|---|---|---|---|

| 0-300 | 10 | Stainless Steel | 1/4 | 2.5 |

| 0-1500 | 25 | Aluminum | 3/8 | 3.0 |

| 0-2000 | 50 | Brass | 1/2 | 4.0 |

| 0-500 | 15 | Plastic | 1/4 | 1.5 |

| 0-1000 | 30 | Inconel | 3/8 | 5.0 |

Safety Features to Look for in Hydrogen Pressure Regulators

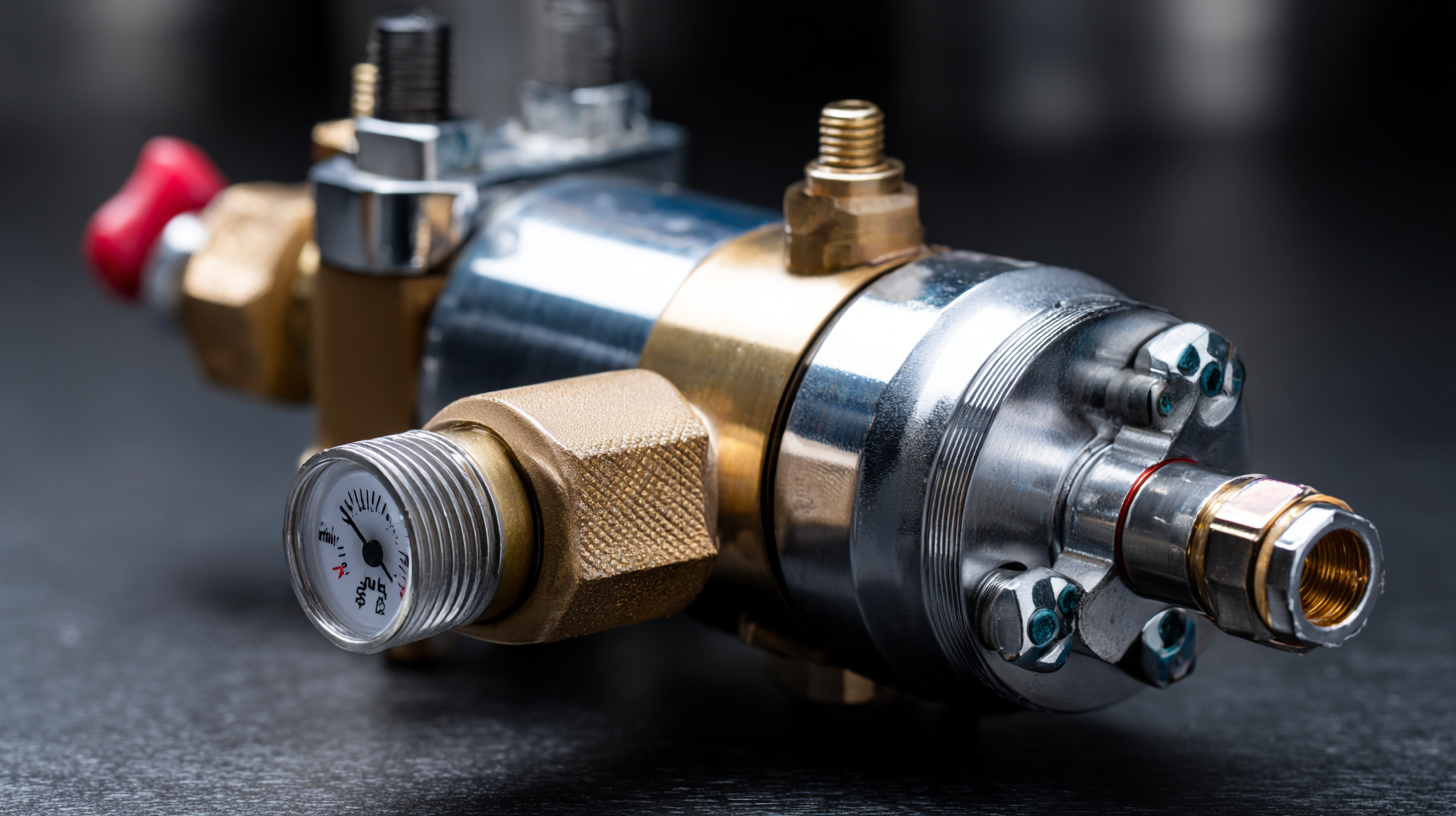

When selecting a hydrogen pressure regulator, safety should be at the forefront of your decision-making process. Look for regulators that are equipped with robust safety features such as over-pressure protection. This prevents dangerous gas buildup, reducing the risk of explosion or system failure. Additionally, consider models that include integrated relief valves; these can automatically release excess pressure, maintaining a safe operating environment.

Another essential safety feature is a monitoring gauge. With a clear, easy-to-read display, you can continuously track pressure levels, ensuring that they remain within safe parameters. It's also wise to choose regulators made from non-corrosive materials, as hydrogen can be highly reactive. Robust construction minimizes risks associated with wear and tear, enhancing overall safety during operation.

Lastly, always opt for regulators that come with comprehensive manufacturer documentation. This should include safety guidelines and maintenance schedules to help you ensure safe and effective usage. Selecting a hydrogen pressure regulator with these essential safety features will not only protect your operations but also provide peace of mind.

Hydrogen Pressure Regulators: Safety Features Comparison

This bar chart illustrates the importance of various safety features that should be considered when choosing a hydrogen pressure regulator. Each feature is rated on a scale of 1 to 10, indicating its significance in ensuring safety during hydrogen handling.

Maintenance Tips for Ensuring Longevity of Your Hydrogen Pressure Regulator

When it comes to maintaining the longevity of your hydrogen pressure regulator, regular upkeep is essential. One of the first steps is to ensure that the regulator is kept clean and free from any contaminants. Regularly inspecting for dust, dirt, or corrosion can help prevent malfunctions and ensure consistent performance. Additionally, it’s important to check the seals and connections for any signs of wear and tear, as these components are critical for maintaining an effective seal under pressure.

Another key tip for prolonging the life of your hydrogen pressure regulator is to monitor its usage and environment. Operate within the manufacturer’s recommended pressure limits and avoid exposing the regulator to extreme temperatures, moisture, or aggressive chemicals. Utilizing protective casings or enclosures can also shield the regulator from unnecessary stressors. By following these maintenance tips, you can ensure that your hydrogen pressure regulator performs optimally and lasts longer, ultimately enhancing the efficiency of your hydrogen systems.