The Future of Precision Control: Innovations in Flow Regulator Technology

As industries continue to embrace automation and precision in their operations, the role of flow regulators becomes increasingly critical in enhancing process efficiency and accuracy. According to a report by MarketsandMarkets, the global market for flow regulation technology is projected to reach USD 8.9 billion by 2025, growing at a CAGR of 5.4%.

These innovations in flow regulator technology not only improve the precision of fluid control across various applications—ranging from manufacturing to HVAC systems—but also contribute to energy savings and reduced operational costs. With advancements such as smart flow regulators equipped with IoT capabilities, businesses can now monitor and adjust flow rates in real-time, ensuring optimal performance and minimal waste.

This blog will delve into the various benefits of flow regulators, shedding light on how these innovations are shaping the future of precision control in diverse industries.

Understanding the Basics: What are Flow Regulators and Their Importance in Precision Control

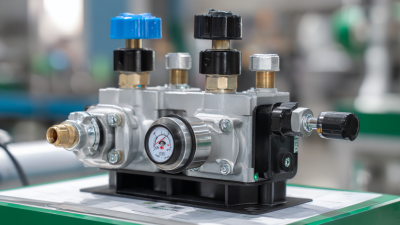

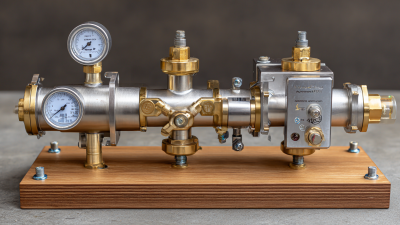

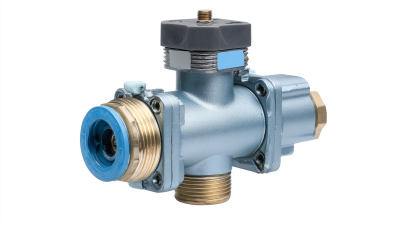

Flow regulators play a pivotal role in precision control across a wide range of industries, ensuring that processes operate smoothly and efficiently. These devices regulate the flow of liquids and gases, maintaining optimal conditions for various applications, from industrial manufacturing to medical devices. Understanding their mechanisms can significantly enhance operational precision. As highlighted in recent studies, innovations in flow regulator technology have evolved to incorporate advanced materials and automation, which allow for real-time adjustments and improved performance metrics.

Tip: Incorporate smart flow regulators equipped with IoT capabilities to facilitate data-driven decision-making and enhance responsiveness in your operations.

Moreover, emerging research in related fields, such as cancer epigenetics, underscores the importance of precise control at a molecular level. Similar to how flow regulators adjust fluid dynamics, researchers are focusing on fine-tuning gene expression to target specific biological processes effectively. The complexity of these interactions indicates that as we embrace innovations in flow control, we might also draw parallels to the precision required in biomedical applications, illustrating the essential nature of precision regulation across disciplines.

Tip: Regularly review your flow regulation systems for potential upgrades that leverage the latest technological advancements to stay ahead in your industry.

Recent Advances in Flow Regulator Technology: Key Innovations and Trends to Watch

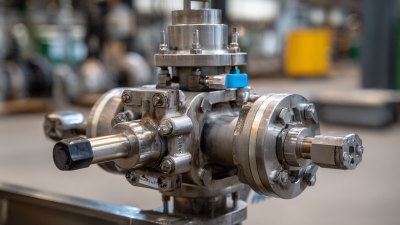

Recent advances in flow regulator technology are reshaping precision control across various industries. Notably, innovations in smart sensors and IoT integration are enhancing the accuracy and efficiency of flow regulation. These technologies allow for real-time monitoring and adjustments, minimizing waste and improving process reliability. The use of advanced materials is also noteworthy; they not only increase the durability of flow regulators but also enable operations under extreme conditions, which is essential for applications in sectors like pharmaceuticals and chemicals.

Tips for selecting the right flow regulator technology include assessing the specific application requirements. Consider the flow range, pressure ratings, and the type of fluid involved to ensure optimal performance. Additionally, keep an eye on the latest developments in automation and remote control features, as these can significantly reduce manual intervention and boost efficiency.

Moreover, it's advisable to stay informed about the trends in sustainability and energy efficiency in flow regulation. Many manufacturers are now prioritizing eco-friendly designs and materials, which not only help in reducing the carbon footprint but also comply with increasing regulatory demands. Keeping abreast of such trends can help businesses choose regulators that align with both operational goals and environmental standards.

The Future of Precision Control: Innovations in Flow Regulator Technology

This chart illustrates the impact scores of various innovations in flow regulator technology, highlighting key trends that are shaping the future of precision control. Each innovation represents a substantial enhancement in operational efficiency and effectiveness.

How Precision Control Enhances Efficiency: The Role of Advanced Flow Regulators

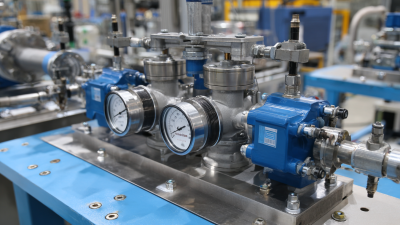

The evolution of flow regulator technology has significantly transformed the landscape of precision control across various industries. Advanced flow regulators utilize sophisticated algorithms and real-time feedback mechanisms, allowing for unprecedented levels of accuracy in fluid management. This precision is crucial in sectors such as pharmaceuticals, chemical manufacturing, and environmental systems, where even minor fluctuations in flow can lead to inefficiency or product defects. By maintaining optimal flow rates, these regulators not only enhance productivity but also reduce waste, leading to cost savings and a smaller environmental footprint.

Moreover, the integration of smart technologies, such as IoT capabilities, enables enhanced monitoring and data analysis. This connectivity allows companies to adapt swiftly to changing operational conditions, ensuring sustained performance and reliability. As industries continue to prioritize efficiency and sustainability, the role of advanced flow regulators becomes increasingly prominent. By leveraging innovations in precision control, businesses can maximize their operational effectiveness while meeting stringent regulatory standards and consumer demands. The future of flow regulation heralds a new era of efficiency, enabling industries to operate at their best.

Practical Applications of Flow Regulators: Industries Transforming Through Innovation

Flow regulators have emerged as essential components in various industries, revolutionizing processes from manufacturing to agriculture. In manufacturing, precision control over fluid delivery ensures consistency in product quality. For instance, in the pharmaceutical sector, flow regulators maintain the sterile conditions critical for developing medications, thus directly impacting patient safety. Additionally, these devices help manage the flow in chemical processes, minimizing waste and enhancing efficiency.

In the agricultural sector, precision irrigation systems utilize flow regulators to optimize water usage, supporting sustainable practices. By delivering the right amount of water directly to the roots of plants, farmers can significantly reduce water consumption while improving crop yields. The implementation of these technologies not only promotes environmental responsibility but also allows for better management of resources in times of drought.

Tip: When considering flow regulator installation, ensure that the selected model matches the specific requirements of your application for maximum efficiency. Tip: Regular maintenance of flow regulators can prevent costly downtime and ensure continuous operational effectiveness, keeping your processes running smoothly.

Future Trends: Predicting the Next Generation of Flow Regulator Technologies

As we look ahead to the future of precision control, one of the most exciting areas of innovation is in flow regulator technology. The next generation of these devices promises not only enhanced accuracy but also greater adaptability to a variety of applications. Emerging trends suggest that integration with smart technologies, such as IoT devices, will become commonplace, allowing for real-time monitoring and adjustments to flow rates based on dynamic conditions. This capability is essential in industries ranging from pharmaceuticals to agriculture, where precise control can significantly impact efficiency and safety.

Moreover, advancements in materials science are paving the way for flow regulators that are more durable and resilient. The development of smart materials that can respond to environmental changes will enable flow regulators to maintain optimal performance without frequent manual interventions. Additionally, artificial intelligence will play a pivotal role in predicting flow patterns and adjusting settings proactively, thus enhancing the overall efficiency of systems that rely on precise fluid management. Overall, the future of flow regulator technology is set to redefine standards, fostering a new era of precision and reliability in fluid control.

The Future of Precision Control: Innovations in Flow Regulator Technology

| Technology Type | Key Features | Applications | Future Trends |

|---|---|---|---|

| Electronic Flow Regulators | Enhanced accuracy, remote monitoring capabilities | Chemical processing, water treatment | Integration with IoT, AI-based flow optimization |

| Smart Flow Meters | Real-time data analytics, predictive maintenance | Oil and gas, HVAC systems | Increased automation, improved data accuracy |

| Microflow Control Systems | Miniaturized components, lower flow rates | Medical devices, laboratory applications | Development of nanotechnology-based systems |

| Analog Flow Regulators | Simplicity, ease of calibration | Industrial processes, water control | Transition to hybrid technologies |

| Adaptive Flow Control | Self-tuning, response to variable conditions | Power generation, thermal management | Growth in renewable energy applications |

Related Posts

-

Unveiling China's Leading Electronic Pressure Regulators for Global Procurement Success

-

Understanding Pressure Regulators for Optimal Performance in Industrial Applications

-

5 Tips for Choosing the Best Hydraulic Pressure Regulator for Your Needs

-

5 Essential Tips for Choosing the Best Hydrogen Pressure Regulator

-

Understanding the Functionality of the Best Back Pressure Valve

-

Embracing Industry 2025 Innovations for the Ultimate Water Pressure Regulator Valve Solutions