How to Identify Top Quality Manufacturers for the Best Pressure Regulator

In the ever-evolving industrial landscape, the demand for high-quality pressure regulators has surged, driven by the increasing need for precision in various applications such as manufacturing, HVAC, and biomedical systems. According to a recent market research report by Grand View Research, the global pressure regulator market is projected to reach USD 5.8 billion by 2025, highlighting its critical role in ensuring safety and efficiency in fluid and gas systems. As industries seek to optimize operations and reduce costs, identifying top-quality manufacturers of pressure regulators becomes paramount. This blog will delve into the top strategies for evaluating potential suppliers, ensuring that businesses can make informed decisions that enhance their operational reliability and regulatory compliance.

Criteria for Evaluating Pressure Regulator Manufacturers in the Industry

When seeking top-quality manufacturers for pressure regulators, it's crucial to establish clear criteria for evaluation. One key aspect to consider is the manufacturer's industry experience. Established manufacturers tend to have a deeper understanding of the market demands and regulatory standards, which can greatly influence the reliability and performance of their products.

**Tip:** Look for manufacturers with at least five years in the industry, as they are more likely to have refined their processes and product offerings.

Another important criterion is the manufacturer's certifications and quality control processes. Certifications such as ISO 9001 can indicate a commitment to high standards, while a robust quality assurance system ensures that each product meets stringent performance criteria before it reaches the customer.

**Tip:** Request detailed information about their quality control measures to gauge their commitment to producing reliable pressure regulators.

Finally, consider the manufacturer’s customer service and support. A responsive team can provide invaluable assistance in troubleshooting or sourcing components, leading to a smoother relationship over time.

**Tip:** Test their customer service by reaching out with questions and gauge their response time and willingness to assist.

Evaluation Criteria for Top Quality Pressure Regulator Manufacturers

Understanding Different Types of Pressure Regulators and Their Applications

When it comes to pressure regulators, understanding the various types and their applications is crucial for selecting the right one for your needs. Pressure regulators can be categorized into several types, including spring-loaded, diaphragm, and electronic models. Spring-loaded regulators are commonly used in industrial applications due to their simplicity and reliability. They maintain a predetermined pressure by utilizing a spring mechanism, making them suitable for a wide array of gases and liquids.

On the other hand, diaphragm regulators provide excellent control and are often utilized in sensitive environments where precision is paramount, such as in laboratories or medical settings. Their design allows for better pressure stabilization, making them ideal for applications requiring consistent output pressure. Lastly, electronic pressure regulators offer advanced features, including programmable settings and real-time monitoring, which are beneficial in automated systems. Understanding these types helps in identifying the right manufacturer who specializes in producing high-quality regulators tailored to specific applications, ensuring optimal performance and safety.

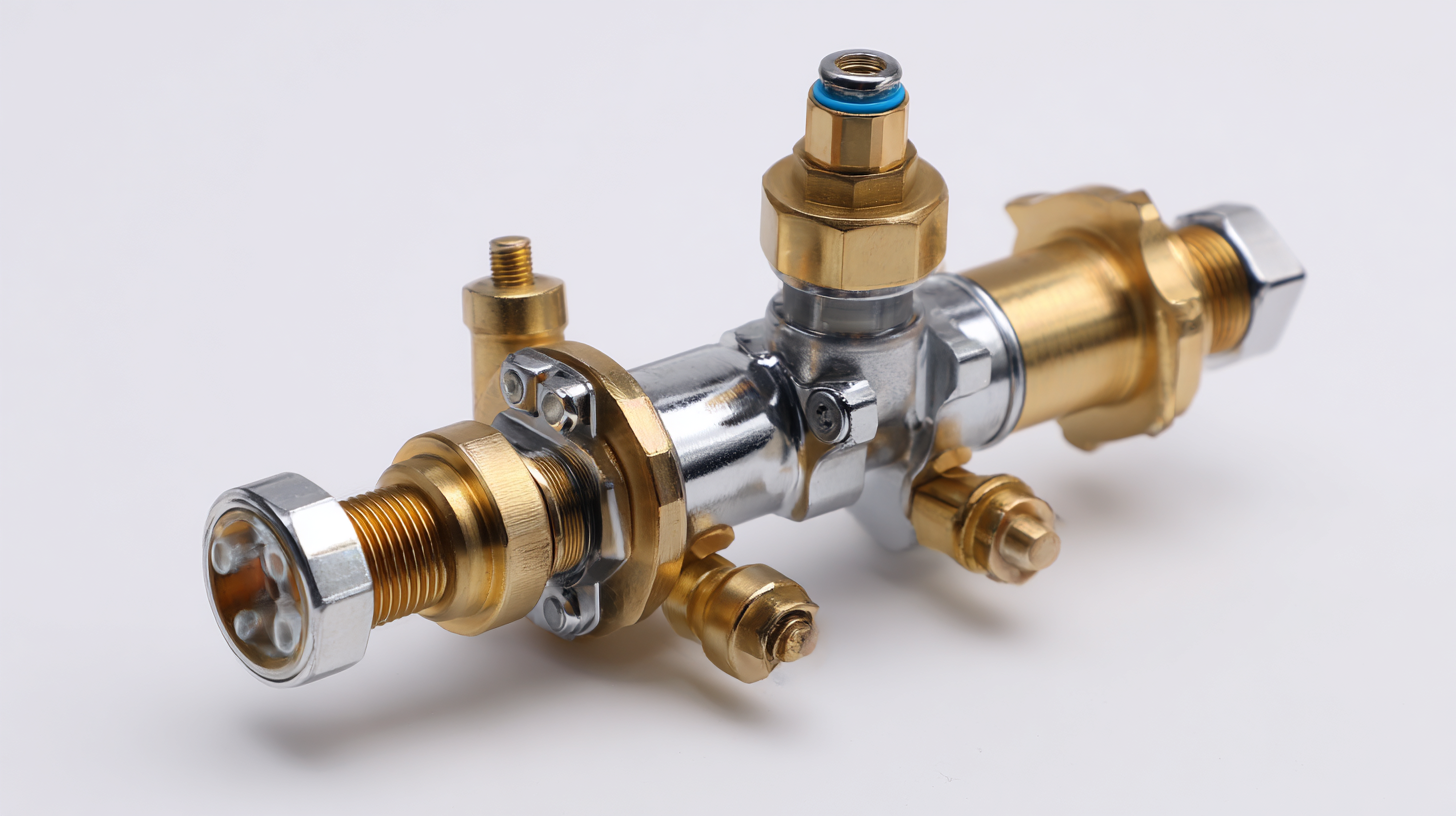

Key Features to Look for in High-Quality Pressure Regulators

When evaluating high-quality pressure regulators, there are several key features that should not be overlooked. First and foremost, flow rate capabilities are critical. According to a recent report by the International Journal of Pressure and Flow, top-performing pressure regulators can maintain consistent flow rates even under varying upstream pressures, with variability as low as 1%. This consistency ensures that systems operate efficiently and helps prevent equipment damage.

Another crucial aspect to consider is the materials used in the regulator's construction. High-quality models often feature stainless steel or brass components, which can deliver greater durability and resistance to corrosion. Industry studies indicate that regulators constructed from superior materials can have a lifespan that is up to 30% longer than those made from lower-quality alternatives. Additionally, precision in manufacturing is vital, with specifications for tolerance levels often recommended to be within ±0.5%. This precision ensures smoother operation and enhanced performance over time, making it a critical factor when selecting a reliable manufacturer.

The Importance of Certifications and Standards in Manufacturer Selection

When selecting high-quality manufacturers for pressure regulators, understanding the importance of certifications and standards is crucial. Certifications like ISO 13485, which focus on quality management systems in medical devices, are indicative of a manufacturer’s commitment to maintaining rigorous quality control and adhering to industry regulations. A recent study highlighted that companies with recognized certifications are perceived as more reliable by consumers, which can significantly influence purchasing decisions. In fact, products boasting sustainability certifications experience sales growth, reflecting a broader consumer trend favoring environmentally responsible practices.

Moreover, the focus on sustainable sourcing has never been more pertinent. Research indicates that 30% of materials sourced by industries should be recycled by 2025 to meet regulatory standards and consumer demands. As companies increasingly pursue transparency in their supply chains, the integration of sustainability practices becomes a benchmark for evaluating potential suppliers. These initiatives not only contribute to a firm’s reputation but also align with the growing expectation from consumers who prioritize sustainable products. Therefore, when assessing manufacturers for pressure regulators, ensure they hold relevant certifications and are committed to sustainable practices to meet both regulatory and consumer expectations.

Building a Relationship with Manufacturers for Long-Term Quality Assurance

Building a strong relationship with manufacturers is crucial for ensuring long-term quality assurance in the production of pressure regulators. A collaborative approach allows both parties to engage in open dialogue, fostering trust and mutual understanding. It is essential to establish clear communication channels that facilitate feedback and ensure that quality standards are not only met but continuously improved. The implementation of effective Supplier Relationship Management practices, such as performance monitoring and regular assessments, can significantly enhance product quality, creating a win-win scenario for manufacturers and buyers alike.

Furthermore, embracing the principles of Total Quality Management can elevate the dynamics of these relationships. By prioritizing quality in every aspect of the production process, manufacturers can effectively reduce supply chain risks and lead time variability. This results in more efficient operations and greater customer satisfaction. Ultimately, developing a multi-directional relationship with manufacturers, characterized by collaboration and trust, can lead to improved supply chain performance and a higher-quality product, ensuring that organizations remain competitive in an ever-evolving market landscape.