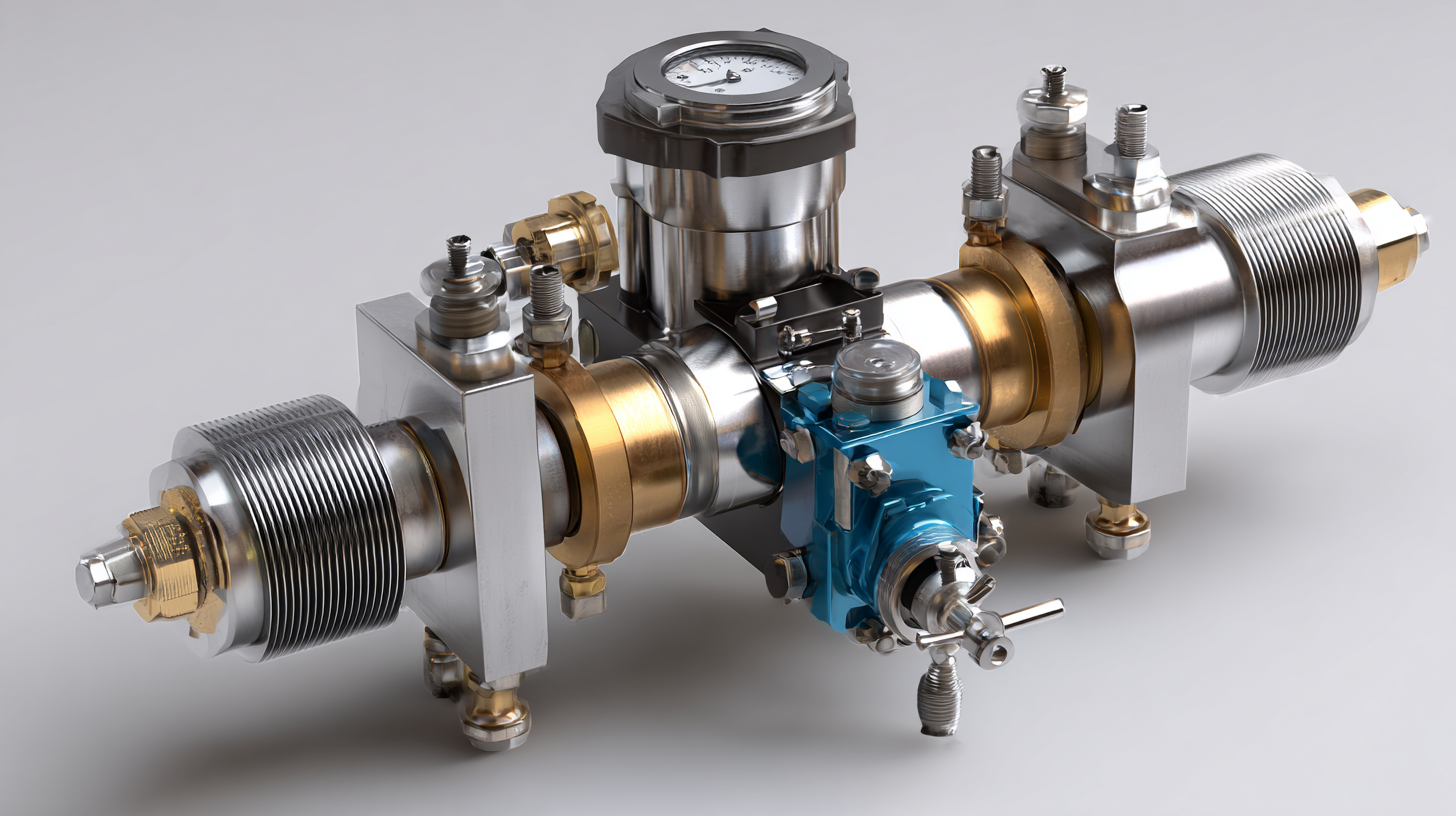

Innovative Alternatives in High Pressure Gas Regulators for 2025 Technological Advancements

In the rapidly evolving landscape of industrial technology, the demand for efficient and reliable high pressure gas regulators has never been more critical. According to a recent report by MarketsandMarkets, the global gas regulator market is expected to reach USD 3.8 billion by 2025, driven by advancements in safety and efficiency protocols across various sectors, including oil and gas, chemicals, and manufacturing. As industries strive to meet stringent regulations and enhance operational performance, innovative alternatives in high pressure gas regulators are set to play a pivotal role.

These developments promise not only improved pressure control and flow dynamics but also the integration of smart technologies for real-time monitoring and predictive maintenance. This blog will explore the upcoming technological advancements in high pressure gas regulators, focusing on how these innovations will shape the industry landscape in the coming years.

Innovative Approaches to After-Sales Service for High Pressure Gas Regulators

In the rapidly evolving world of high-pressure gas regulators, after-sales service is emerging as a critical factor differentiating leading companies from their competitors.

Innovative approaches to after-sales service are not merely about maintenance and repairs; they encompass a comprehensive strategy to enhance customer experience and operational efficiency.

By leveraging digital platforms, manufacturers can facilitate real-time monitoring of gas regulator performance, ensuring timely interventions and minimizing downtime for users.

Furthermore, the integration of augmented reality (AR) tools into after-sales service provides technicians with interactive troubleshooting support.

This technology allows for remote assistance, guiding users step-by-step through maintenance procedures without the need for an on-site visit. Additionally, proactive customer education programs that utilize webinars and online resources empower users to maximize the efficiency and lifespan of their gas regulators.

Collectively

,these innovative after-sales strategies are set to redefine user satisfaction and loyalty in the high-pressure gas regulator market.

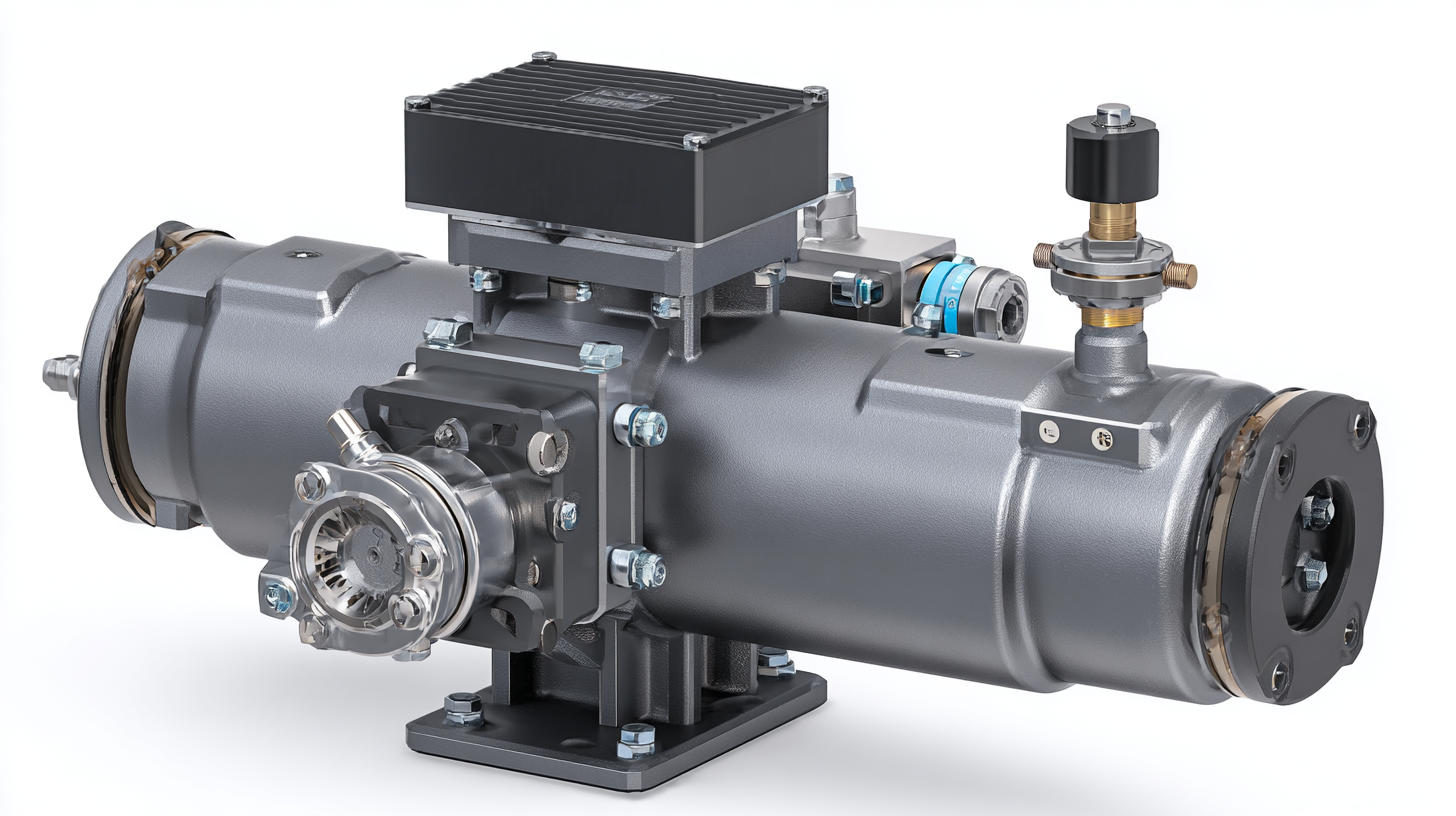

Impact of Technological Advancements on Maintenance Costs in Gas Regulation

As the industry progresses towards 2025, the impact of technological advancements on maintenance costs in gas regulation systems is becoming increasingly significant. With innovations in high pressure gas regulators, we are witnessing a shift towards more efficient designs that not only improve performance but also reduce the frequency and expense of maintenance. Advanced materials and smart technologies are enabling regulators to perform more reliably, which translates to less downtime and lower operational costs for businesses.

Tips: Regularly investing in training for technicians can ensure they are up-to-date with the latest innovations, which may help in quickly diagnosing and rectifying any issues. Furthermore, incorporating predictive maintenance tools can help anticipate potential failures, allowing for maintenance to be performed more efficiently, thus saving costs in the long run.

Additionally, manufacturers are now providing enhanced support and warranties with their products, which can alleviate the financial burdens of unexpected repairs. Choosing regulators equipped with self-diagnostic features means that minor issues can be resolved before they escalate, cementing a proactive maintenance approach. Embracing these advancements not only ensures enhanced safety but also contributes to better financial management and sustainability in gas operations.

Innovative Alternatives in High Pressure Gas Regulators for 2025 Technological Advancements - Impact of Technological Advancements on Maintenance Costs in Gas Regulation

| Technology Type | Cost Reduction (%) | Maintenance Frequency (times/year) | Expected Lifespan (years) | Environmental Impact (Low/Medium/High) |

|---|---|---|---|---|

| Smart Regulators | 25% | 2 | 10 | Low |

| Electronic Control Systems | 30% | 3 | 12 | Medium |

| Composite Materials | 20% | 1 | 15 | Low |

| AI-Driven Monitoring | 40% | 2 | 8 | Medium |

| Hybrid Systems | 35% | 1 | 14 | Low |

Data Trends: Customer Satisfaction in After-Sales Services for Gas Equipment

The customer satisfaction landscape for after-sales services in the gas equipment sector is undergoing significant transformation as we approach 2025. With technological advancements reshaping service capabilities, more companies are recognizing the critical importance of maintaining high satisfaction levels among their clientele. Recent studies indicate that the service experience is pivotal for customer retention, especially in the context of the lingering pandemic effects which have subtly influenced expectations. As the handyman service industry grows, projected to reach USD 1,579.14 million by 2033, it is vital for businesses to adapt their service models to meet evolving customer needs.

One of the key findings from the 2023 U.S. Customer Service Index study is the slight decline in satisfaction scores, highlighting an urgent need for companies to enhance their after-sales services. Consumers today are looking for not just quality products but also reliable support and guidance post-purchase. Investing in advanced customer service technologies, such as AI-driven solutions, can empower service representatives to resolve issues efficiently. As innovation in high pressure gas regulators continues, aligning these advancements with strong after-sales service strategies will be crucial in fostering customer loyalty and maintaining a competitive edge in the market.

Comparative Analysis of Warranty Policies and Repair Services in the Industry

The high-pressure gas regulator market is witnessing significant advancements in warranty policies and repair services as industry players aim to enhance customer satisfaction and product longevity. A recent report indicates that the extended warranty market associated with such equipment is expected to grow, with projections estimating a value of over $5 billion by 2025. This surge can be attributed to the increasing reliance on high-pressure gas systems across various sectors, prompting manufacturers to offer more comprehensive warranty options, including standard and accidental protection plans.

For consumers, understanding the nuances of warranty policies can make a substantial difference. It is vital to compare coverage details, service responsiveness, and overall support that different brands provide. Some companies even offer on-site repair services, which can significantly reduce downtime and operational costs. When evaluating options, consider not only the price but also the extent and duration of coverage, as these factors directly impact long-term value.

**Tips:** Always read the fine print of warranty agreements, paying particular attention to exclusions and limitations. Additionally, inquire about the availability of customer support and repair services to ensure a seamless experience in case of product issues. Finally, look for feedback from existing customers to gauge the effectiveness and reliability of the warranty services provided.

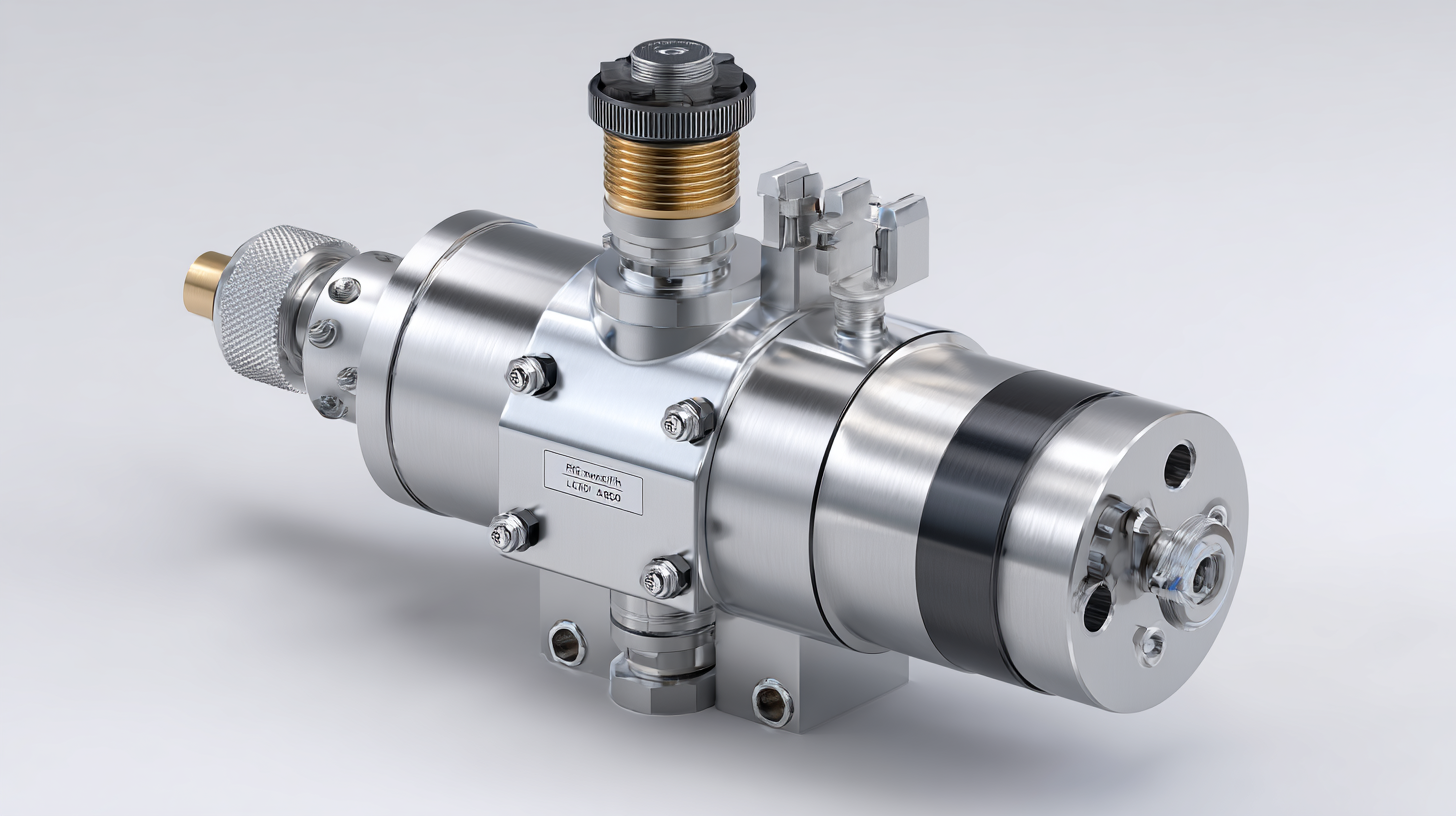

Future-Proofing Maintenance Strategies for High Pressure Gas Regulators by 2025

As we look towards 2025, the maintenance strategies for high-pressure gas regulators need to evolve in tandem with technological advancements. Innovations in materials and design are set to enhance the reliability and efficiency of these essential components. To future-proof your maintenance approach, consider integrating predictive maintenance tools that leverage data analytics. This proactive method not only minimizes downtime but also extends the life of your regulators by addressing potential issues before they escalate.

Tip: Regularly monitor the performance of your gas regulators using IoT-enabled sensors. These devices can provide real-time data on pressure levels and flow rates, allowing for immediate adjustments and repairs when necessary. This data-driven approach ensures your systems are always operating at peak efficiency.

Additionally, investing in advanced training for maintenance staff can greatly impact their ability to perform effective troubleshooting and repairs. Familiarity with the latest technologies and best practices will empower your team to implement timely interventions, thus maximizing the safety and productivity of your gas management systems.

Tip: Create a continuous learning environment by hosting quarterly workshops that focus on emerging technologies and maintenance techniques. Engaging your workforce in these discussions ensures they stay updated on the latest advancements and maintain high levels of operational readiness.