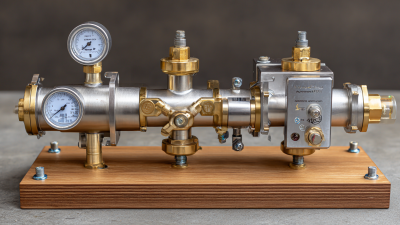

Innovative Solutions for Effective Temperature Control Valve Integration

In today's rapidly evolving industrial landscape, the integration of innovative solutions for temperature control valve systems is more critical than ever. According to a recent report by MarketsandMarkets, the global market for temperature control valves is projected to reach $6.22 billion by 2025, growing at a CAGR of 5.9%. This growth is driven by the increasing need for precise temperature management in various applications, including HVAC systems, chemical processing, and food and beverage industries. Effective temperature control valves are essential for maintaining operational efficiency, improving safety, and optimizing energy consumption. As industries strive to enhance their process control strategies, understanding the latest technologies and methodologies in temperature control valve integration becomes imperative. This ultimate guide aims to provide insights into innovative solutions that not only improve performance but also facilitate seamless integration into existing systems, ensuring that businesses stay competitive in a challenging market.

Understanding the Basics of Temperature Control Valves in Industrial Applications

Temperature control valves play a vital role in ensuring optimal functioning within various industrial applications. Understanding their fundamentals is essential for industries dealing with temperature-sensitive processes. The global cryogenic valve market, which encompasses temperature control valves, was valued at approximately $4.14 billion in 2023 and is projected to reach $9.73 billion by 2032. This growth reflects the increasing demand for precise temperature regulation across sectors such as pharmaceuticals, food processing, and energy, where maintaining specific temperature ranges is crucial for quality and efficiency.

Advancements in technology, particularly machine learning and the Internet of Things (IoT), are enhancing the capabilities of temperature control systems. These innovations allow for real-time monitoring and adjustments, ensuring consistent performance and reducing energy consumption. For instance, the ability to integrate smart sensors with temperature control valves can significantly improve water quality management in various industrial processes. As industries continue to evolve, investing in effective temperature control solutions will be essential for maintaining competitiveness and meeting regulatory standards.

Key Factors to Consider for Successful Valve Integration in Temperature Control Systems

In the realm of temperature control valve integration, several key factors play a crucial role in ensuring successful implementation within control systems. The recent report indicates that the global temperature control unit market is expected to grow from $1.5 billion in 2025 to approximately $2.44 billion by 2035, showcasing a robust CAGR of 5%. This growth is largely driven by the increasing demand for efficient temperature management across various industries, necessitating the integration of innovative valve solutions that enhance control accuracy while minimizing energy consumption.

Moreover, as advancements in technology continue to shape temperature control systems, automatic and intelligent solutions are becoming imperative. For instance, integrating smart algorithms and IoT capabilities can significantly enhance system responsiveness and operational efficiency. Reports suggest that employing machine learning models in temperature control systems can lead to optimized energy use, reduced operational costs, and improved performance. Consequently, the selection and integration of temperature control valves must consider factors such as compatibility with smart technologies, energy efficiency, and scalability to ensure efficacy in future applications.

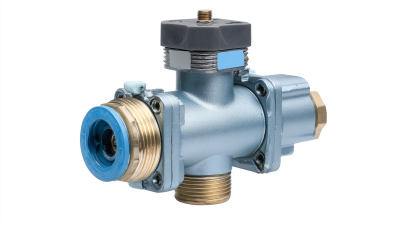

Step-by-Step Guide to Selecting the Right Temperature Control Valve

When selecting the right temperature control valve, it is critical to understand the specific requirements of your application. According to the Market Research Future report, the global temperature control valve market is expected to grow at a CAGR of 6.5% from 2021 to 2026, primarily driven by advancements in industrial automation and the increasing demand for precise temperature regulation across various sectors. This highlights the importance of investing in the appropriate valve technology to enhance operational efficiency.

The selection process begins with determining the type of media being controlled—whether gas or liquid—and understanding the temperature range and flow characteristics. For instance, a study from Frost & Sullivan emphasizes that using the correct valve type can improve energy efficiency by up to 30%. After identifying these parameters, it’s essential to consider the valve's size, material compatibility, and control mechanism (such as modulating or on/off) based on the application’s needs. Engaging with suppliers who provide comprehensive technical data and support can significantly simplify this process, ensuring you make an informed choice that aligns with industry standards and performance requirements.

Temperature Control Valve Performance Comparison

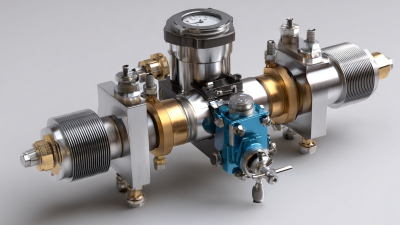

Innovative Technologies Enhancing Temperature Control Valve Performance

In the ever-evolving landscape of industrial automation, temperature control valves play a crucial role in maintaining optimal operational efficiency. Recent advancements in innovative technologies are enhancing the performance of these vital components. Smart sensors and IoT connectivity are paving the way for real-time monitoring, enabling operators to respond swiftly to changes in system temperatures. This integration allows for predictive maintenance, reducing downtime and prolonging the lifespan of equipment.

Tip: Consider investing in smart temperature control valves that provide data analytics. This can help you identify trends and optimize processes, ultimately leading to improved energy efficiency.

Moreover, the development of advanced materials and designs is driving improvements in valve durability and responsiveness. Enhanced seal technology ensures improved reliability under varying conditions, while faster actuator responses enable more precise control of temperature variations. These innovations not only improve the overall effectiveness of temperature control systems but also contribute to energy savings by minimizing thermal losses.

Tip: Regularly assess your current temperature control solutions. Upgrading to the latest valve technologies can lead to significant operational improvements and cost savings over time.

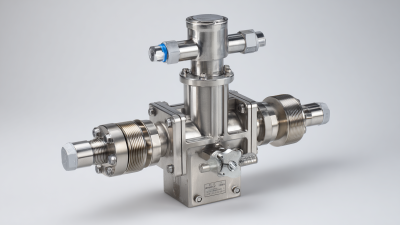

Troubleshooting Common Issues in Temperature Control Valve Integration

Temperature control valves are critical components in various industrial applications, ensuring optimal operational conditions. However, the integration of these valves can pose several challenges. According to a recent report by the International Society of Automation, approximately 30% of temperature control valve failures are attributed to improper installation and configuration. This statistic underscores the importance of meticulously troubleshooting common issues during the integration process.

One prevalent problem is the mismatch between the valve’s specifications and the system requirements. Industry studies suggest that up to 25% of downtime in temperature control systems can be linked to incorrect sizing and selection of valves. This highlights the necessity for thorough analysis and data verification prior to installation, ensuring that the selected valves are not only compatible with existing systems but also capable of meeting the specific demands of the application.

Additionally, actuator performance can significantly impact the effectiveness of temperature control valves. According to a report by the Flow Control Association, around 40% of actuator failures arise from inadequate power supply or control signal issues. Therefore, it is crucial to establish a reliable communication pathway between the temperature control system and the valve actuators to mitigate these risks. Employing advanced diagnostics and real-time monitoring can effectively enhance the integration process, leading to improved performance and reduced maintenance costs over time.

Related Posts

-

5 Essential Tips for Choosing the Best Hydrogen Pressure Regulator

-

Innovative Alternatives in High Pressure Gas Regulators for 2025 Technological Advancements

-

5 Tips for Choosing the Best Hydraulic Pressure Regulator for Your Needs

-

Embracing Industry 2025 Innovations for the Ultimate Water Pressure Regulator Valve Solutions

-

Common Issues Regarding Back Pressure Regulator Selection and Performance

-

The Future of Precision Control: Innovations in Flow Regulator Technology