Top 10 Low Pressure Regulators for Optimal Gas Control Efficiency

In the evolving landscape of gas control systems, the significance of low pressure regulators cannot be overstated. These devices play a crucial role in ensuring safety and efficiency across various applications, including industrial processes and residential systems. According to the recent report by the Global Gas Regulatory Market Analysis, the demand for reliable low pressure regulators is expected to grow by over 7% annually through 2025, driven by advancements in technology and the increasing emphasis on safety standards.

Expert insights enhance our understanding of this critical segment. Dr. Emily Evans, a renowned authority in gas regulation technologies, remarks, "The evolution of low pressure regulators is pivotal for enhancing both efficiency and safety in gas distribution networks." As industry standards become more stringent, adopting high-quality low pressure regulators is essential for compliance and operational efficiency.

This article will explore the top 10 low pressure regulators available in the market today, focusing on their features, applications, and overall performance. Optimizing gas control not only improves system reliability but also contributes significantly to energy conservation efforts across various sectors, making it an integral part of modern gas management strategies.

Top Features to Consider in Low Pressure Regulators for Gas Control

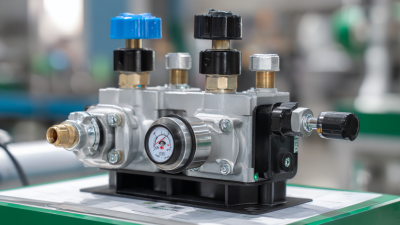

When selecting low pressure regulators for gas control, several key features should be taken into consideration to ensure optimal performance and safety. One of the most important aspects is the pressure range and accuracy of the regulator. Regulators that offer precise pressure settings allow for better control of gas flow, which is crucial in applications such as cooking, heating, or industrial processes. Additionally, look for models with a broad adjustment range that can accommodate various gas types and demands.

Another vital feature is the material and construction of the regulator. High-quality materials ensure durability and resistance to corrosion, which is essential for maintaining efficiency over time. Regulators that feature a robust design with protective features, such as pressure relief valves, help prevent backflow and potential hazards. Furthermore, ease of installation and maintenance should not be overlooked. Choosing a regulator that comes with user-friendly installation instructions and requires minimal upkeep will enhance its overall usability.

Comparison of Material Types for Durability and Performance in Regulators

When selecting low pressure regulators, the type of materials used in their construction plays a crucial role in both durability and performance. Regulators are typically made from materials such as brass, stainless steel, and various polymers. Brass is known for its strength and resistance to corrosion, making it a popular choice for applications where exposure to moisture may occur. Stainless steel, while often more expensive, offers superior resistance to corrosive environments and is essential for demanding industrial applications. On the other hand, polymers can provide lightweight solutions that are resistant to certain chemicals, ideal for less demanding environments.

Tips for selecting the right material: Consider the specific environment your regulator will operate in. If moisture or corrosive substances are present, opt for stainless steel or brass. For environments that require reduced weight, look into high-performance polymers that can withstand the necessary pressures. Additionally, always check for compatibility between the regulator material and the gas being used to ensure performance is not compromised.

Ultimately, the choice of material directly impacts the efficiency and longevity of the gas control system. Understanding the properties and limitations of each material type can lead to better performance outcomes and fewer maintenance issues. Prioritize durability to ensure that the regulator maintains accurate pressure settings over time, providing reliable gas flow in all operational scenarios.

Impact of Flow Rate on Efficiency: Selecting the Right Low Pressure Regulator

When selecting a low pressure regulator, understanding the impact of flow rate on efficiency is crucial. Flow rates directly influence how gas is delivered to a system, and achieving optimal efficiency requires careful consideration of the regulator's design and specifications. A regulator that can handle varying flow rates while maintaining consistent pressure will ensure that the downstream applications receive a stable supply of gas, which is vital for both performance and safety.

Moreover, the relationship between flow rate and efficiency is not linear. As flow rates increase, regulators may encounter challenges such as pressure drops or fluctuations, which can lead to inefficient operation. Therefore, it is essential to choose a low pressure regulator that is specifically engineered for the intended flow range. In practice, this means assessing the maximum and minimum flow rates required for your application and selecting a regulator that can accommodate those needs without compromise. By paying close attention to these factors, users can enhance their system's overall gas control efficiency.

Gas Flow Rate Efficiency of Top 10 Low Pressure Regulators

Industry Standards and Certifications for Low Pressure Regulators Explained

When evaluating low pressure regulators, understanding industry standards and certifications is crucial for ensuring optimal performance and safety. These standards often inform the design and manufacturing processes, helping to establish requirements for material durability, pressure tolerances, and leak prevention. Look for regulators that meet or exceed standard certifications such as UL (Underwriters Laboratories) and ANSI (American National Standards Institute), which indicate that the device has undergone rigorous testing.

Tip: Always check the certification labels on low pressure regulators before purchase to ensure compliance with relevant safety standards. This can save you from potential hazards and enhance the longevity and efficiency of your gas control systems.

Another essential aspect of industry standards is the performance reliability under varying conditions. Low pressure regulators must maintain consistent gas flow, even with fluctuations in input pressure. Certification by organizations such as CSA (Canadian Standards Association) can provide assurance that the product will perform safely under expected environmental stresses.

Tip: Consider the application environment of your regulator, and select one that is rated for those specific conditions. This attention to detail will contribute significantly to the effectiveness and safety of your gas management solutions.

Maintenance Practices to Enhance Longevity and Efficiency of Regulators

Proper maintenance of low pressure regulators is essential for ensuring optimal gas control efficiency and prolonging the lifespan of your equipment. Regular inspections can help identify potential issues before they become significant problems. According to industry reports from the American Society of Mechanical Engineers (ASME), maintaining a clean environment around the regulator and ensuring that it is free from debris can improve its efficiency by up to 15%. Additionally, lubricating moving parts according to the manufacturer's guidelines can prevent wear and tear, enhancing performance.

Tips: Always check for leaks post-maintenance using a suitable leak detection solution. A simple soap and water mixture can effectively reveal the presence of leaks, allowing for timely repairs. Furthermore, replacing worn seals and gaskets at regular intervals based on operational conditions can prevent performance loss and maintain safety.

Incorporating routine testing of pressure settings aligns with best practices outlined in the National Fire Protection Association (NFPA) standards. Ensuring that the regulator is calibrated correctly helps maintain target pressure, minimizing fluctuations that can lead to equipment damage. Keeping a maintenance log can also streamline the maintenance process, providing insights into the performance history and helping to project future service needs.

Top 10 Low Pressure Regulators for Optimal Gas Control Efficiency

| Regulator Model | Pressure Range (psi) | Flow Capacity (scfh) | Material | Maintenance Frequency (months) |

|---|---|---|---|---|

| Model A | 0-30 | 100 | Aluminum | 6 |

| Model B | 0-25 | 80 | Brass | 12 |

| Model C | 0-15 | 60 | Plastic | 9 |

| Model D | 0-35 | 120 | Stainless Steel | 6 |

| Model E | 0-20 | 75 | Aluminum | 12 |

| Model F | 0-40 | 150 | Brass | 6 |

| Model G | 0-10 | 50 | Plastic | 9 |

| Model H | 0-45 | 200 | Stainless Steel | 6 |

| Model I | 0-30 | 85 | Aluminum | 12 |

| Model J | 0-20 | 70 | Brass | 12 |

Related Posts

-

How to Choose the Best Gas Regulator Valve for Optimal Safety and Performance in Industrial Applications

-

The Ultimate Guide to Choosing the Right Gas Pressure Regulator for Optimal System Performance

-

Essential Guide to Choosing the Right High Pressure Gas Regulator for Your Needs

-

8 Proven Best Practices for Optimizing Natural Gas Regulators Performance

-

What is a Pressure Reducing Valve and How Does It Ensure System Efficiency

-

Unveiling China's Leading Electronic Pressure Regulators for Global Procurement Success