How to Optimize Your System with Swagelok Back Pressure Regulators

In today's fast-paced industrial landscape, optimizing system performance is paramount for enhancing efficiency and reducing operational costs. The use of a Swagelok back pressure regulator can be pivotal in achieving these goals, as it effectively manages pressure within fluid systems. According to the International Society for Automation, improper pressure management can lead to a 20% increase in energy consumption, underscoring the need for reliable pressure control solutions. Furthermore, a report by the American Society of Mechanical Engineers highlights that systems equipped with high-quality pressure regulators can improve process reliability by up to 30%. By implementing Swagelok back pressure regulators, businesses can not only maintain precise pressure levels but also extend the lifespan of their equipment, thereby driving overall productivity. This article will delve into the key strategies for optimizing your systems using these advanced pressure regulation solutions.

Understanding Back Pressure Regulators and Their Importance

Back pressure regulators are essential components in fluid systems, ensuring optimal pressure levels that enhance the efficiency and safety of operations. According to a report by the Fluid Controls Institute, improper pressure management can lead to system failures that account for approximately 30% of unplanned downtime in industrial processes. Back pressure regulators automatically adjust the downstream pressure, maintaining it within specified limits, which not only safeguards equipment but also improves system reliability.

In industries such as pharmaceuticals and petrochemicals, the importance of back pressure regulators cannot be overstated. A study published in the Journal of Process Control indicates that using quality regulators can reduce process variability by up to 25%. Swagelok back pressure regulators, known for their precision engineering and durability, play a critical role in maintaining optimal conditions for chemical reactions and material transfer. Their use significantly minimizes the risk of product contamination and ensures compliance with stringent industry standards, underscoring the value of these devices in high-stakes environments.

Optimizing System Performance with Back Pressure Regulators

Key Features of Swagelok Back Pressure Regulators

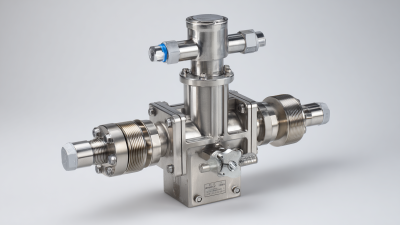

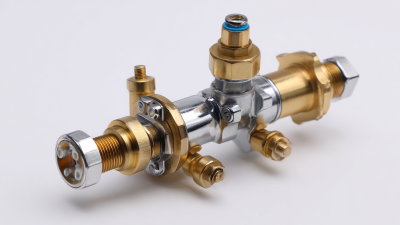

Swagelok back pressure regulators are essential for maintaining optimal system pressure in various applications. One of the key features of these regulators is their precise pressure control, which is crucial for maintaining stability in processes involving gases and liquids. These regulators help prevent pressure spikes that can lead to equipment failure or safety hazards, ultimately enhancing the performance and reliability of your system.

Tips for optimizing your system with these regulators include ensuring proper installation to minimize leaks and pressure drops. Regular maintenance and calibration can also assist in achieving consistent performance. Additionally, consider selecting the appropriate regulator size based on your specific application needs; this will enhance responsiveness and efficiency while reducing operational costs.

Moreover, their robust construction materials make them suitable for demanding environments, extending their lifespan and reliability. Incorporating Swagelok back pressure regulators can significantly improve your system’s efficiency, allowing for smoother operations and increased productivity.

Step-by-Step Guide to Selecting the Right Regulator

When selecting the right Swagelok back pressure regulator for your system, it is crucial to understand the specific needs of your application. Start by determining the pressure range required for optimal performance. Knowing the upstream and downstream pressures will help you identify the appropriate regulator model. Additionally, consider the flow rates that will occur within your system, as this will influence the selection of a regulator that can maintain stability under varying conditions.

Next, evaluate the materials and construction of the Swagelok regulators. Compatibility with the fluids in your system is essential to prevent corrosion and ensure longevity. Look for options that offer different material combinations to match your process requirements. Lastly, assess the installation space available, as some regulators may need more room for maintenance or adjustments. By following these steps, you can confidently choose the right back pressure regulator that enhances the efficiency and reliability of your system.

Best Practices for Installation and Maintenance

Installing and maintaining back pressure regulators is crucial for optimizing system performance, particularly in fluid and gas control applications. Back pressure regulators work by maintaining a set pressure in a system, ensuring that the downstream environment operates effectively. According to industry reports, optimal installation can result in pressure fluctuations being reduced by up to 25%, enhancing system stability.

Tips for Installation: When installing Swagelok back pressure regulators,

ensure that the orientation aligns with your specific application needs.

Mounting them vertically can significantly improve their functionality by utilizing

gravity to assist in the pressure

regulation process. Additionally, the use of proper sealing materials can prevent

leaks, which is vital for maintaining consistent performance and safety.

Tips for Installation: When installing Swagelok back pressure regulators,

ensure that the orientation aligns with your specific application needs.

Mounting them vertically can significantly improve their functionality by utilizing

gravity to assist in the pressure

regulation process. Additionally, the use of proper sealing materials can prevent

leaks, which is vital for maintaining consistent performance and safety.

Maintenance Best Practices: Regular maintenance is essential to keep back pressure regulators in peak condition. It is recommended to implement routine checks every three months to inspect for wear and replace any components as necessary. Utilizing visual monitoring tools can aid in tracking the regulator’s performance and immediate identification of issues. This is echoed by studies indicating that proactive maintenance can extend the operational lifespan of regulators by over 30%.

By following these installation and maintenance best practices, you can help ensure your system remains optimized and reduces the risk of operational disruptions.

Troubleshooting Common Issues with Back Pressure Regulators

When working with Swagelok back pressure regulators, understanding common issues can help enhance system optimization. One prevalent problem is inconsistent pressure control, often arising from clogging or contamination of the regulator. To address this, ensure that the inlet filters are regularly inspected and replaced as necessary. Additionally, regular maintenance of associated piping and fittings can help prevent debris buildup, ensuring a smoother flow through the regulator.

Another common issue is instability in the pressure reading, which can lead to erratic system performance. This could result from fluctuations in the upstream pressure or incorrect settings on the regulator itself. To resolve this, always double-check the regulator's setting against system requirements and confirm that there are no sudden changes in the upstream supply. If instability persists, assessing the regulator’s operational range and potential oversizing or undersizing issues can also offer insights for correction. By troubleshooting these frequent challenges, users can significantly improve the reliability of their back pressure regulators and optimize overall system performance.

How to Optimize Your System with Swagelok Back Pressure Regulators - Troubleshooting Common Issues with Back Pressure Regulators

| Issue | Description | Possible Causes | Solutions |

|---|---|---|---|

| Noisy Operation | Excessive noise during operation. | Improper installation, high flow rates. | Check installation; reduce flow rate. |

| Inconsistent Pressure | Pressure fluctuates outside set range. | Worn seals, blocked orifices. | Replace seals; clean orifice. |

| Leakage | Fluid leaks around the regulator. | Loose fittings, damaged diaphragm. | Tighten fittings; replace diaphragm. |

| Difficulty Adjusting | Regulator does not adjust easily. | Corrosion, debris accumulation. | Clean regulator; check for corrosion. |

Related Posts

-

The Future of Precision Control: Innovations in Flow Regulator Technology

-

5 Tips for Choosing the Best Hydraulic Pressure Regulator for Your Needs

-

Common Issues Regarding Back Pressure Regulator Selection and Performance

-

Understanding the Common Issues Faced with Pressure Regulators in Industrial Applications

-

How to Identify Top Quality Manufacturers for the Best Pressure Regulator

-

How to Choose the Best Gas Regulator Valve for Optimal Safety and Performance in Industrial Applications