8 Proven Best Practices for Optimizing Natural Gas Regulators Performance

In the realm of energy management, the performance of natural gas regulators plays a pivotal role in ensuring the efficiency, safety, and reliability of gas delivery systems. As the demand for natural gas continues to rise, optimizing these regulators becomes crucial for both operational excellence and cost-effectiveness. In this blog, we will delve into eight proven best practices that are designed to enhance the performance of natural gas regulators. By exploring these strategies, professionals in the field can not only maximize the efficiency of their systems but also mitigate risks associated with gas regulation. Whether you're a seasoned engineer or a newcomer to the industry, implementing these best practices will equip you with the tools necessary to uphold the highest standards of performance in natural gas management.

Best Practices for Regular Maintenance of Natural Gas Regulators

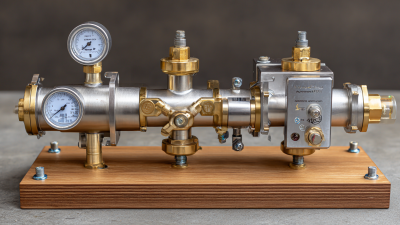

Regular maintenance of natural gas regulators is crucial to ensure optimal performance and safety. A well-maintained regulator can efficiently manage gas flow, preventing fluctuations that could pose risks. One essential tip is to conduct routine inspections every few months. Look for signs of wear, leaks, or any corrosion that may affect functionality. Keeping the regulator clean and free from debris also plays a vital role in its longevity and effectiveness.

Another important practice is to check the inlet and outlet pressure regularly. This ensures that the regulator is working within its designed specifications. Adjustments may be needed if there are significant deviations. Additionally, consider implementing a logbook for maintenance activities, which helps track the performance over time and identifies patterns that might indicate future issues.

Finally, always ensure that your maintenance crew is well-trained and familiar with the latest industry standards. Investing in proper training not only enhances their skills but also promotes adherence to safety protocols. A proactive maintenance approach, combined with knowledgeable personnel, can significantly improve the reliability and performance of natural gas regulators.

Essential Monitoring Techniques for Enhanced Gas Regulator Performance

Effective monitoring is crucial for enhancing the performance of natural gas regulators. One fundamental technique involves the regular inspection of pressure readings. By consistently tracking the inlet and outlet pressures, operators can identify any fluctuations that may indicate underlying issues. This proactive approach allows for timely interventions, preventing costly disruptions and ensuring a continuous supply of gas. Additionally, employing pressure gauges with higher precision can help detect even minor deviations that could affect the overall system's efficiency.

Another essential monitoring technique is the implementation of smart technologies. Utilizing digital sensors and IoT (Internet of Things) connectivity can significantly improve real-time data collection and analysis. By integrating these technologies into gas regulation systems, operators can receive immediate alerts regarding abnormal conditions, such as pressure spikes or drops. This data-driven approach enables more informed decisions and enhances predictive maintenance efforts, ultimately optimizing the performance and lifespan of gas regulators. By focusing on these essential monitoring techniques, operators can ensure reliable and efficient performance of their natural gas systems.

Key Factors Influencing Natural Gas Regulator Efficiency

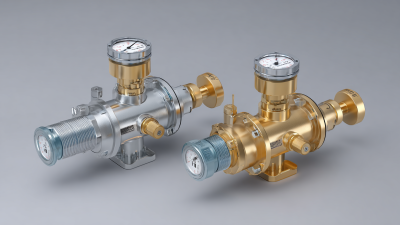

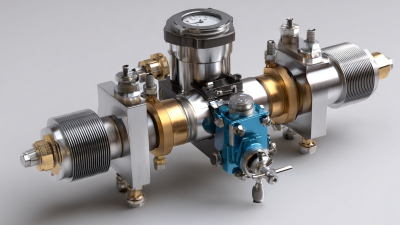

Optimizing the performance of natural gas regulators relies heavily on several key factors that influence their efficiency. One of the primary elements is the design and engineering of the regulator itself. Regulators equipped with advanced materials and precise manufacturing techniques tend to offer better performance, ensuring consistent pressure control and minimizing the risk of failures. Additionally, the integration of technology such as smart sensors can lead to real-time monitoring and adjustments, allowing for greater responsiveness to fluctuating gas demands.

Another critical factor impacting the efficiency of natural gas regulators is regular maintenance and calibration. Frequent inspections and timely upkeep can prevent the degradation of components, which is essential for maintaining optimal functioning. Proper calibration ensures that the regulators operate within specified parameters, reducing energy losses and improving overall safety during operation. Moreover, training personnel to understand the operation and maintenance of these devices can further enhance their reliability and longevity, ultimately contributing to a more efficient natural gas distribution system.

8 Proven Best Practices for Optimizing Natural Gas Regulators Performance - Key Factors Influencing Natural Gas Regulator Efficiency

| Best Practices | Description | Impact on Efficiency (%) | Implementation Cost (USD) |

|---|---|---|---|

| Regular Maintenance | Scheduled checks and servicing of regulators to prevent failures. | 15 | 500 |

| Proper Sizing | Using correctly sized regulators to match gas flow requirements. | 20 | 300 |

| Temperature Monitoring | Monitoring and adjusting temperatures to optimize gas flow. | 10 | 200 |

| Pressure Regulation | Maintaining consistent pressure levels to ensure stable operation. | 25 | 400 |

| Leak Detection Systems | Implementing systems to identify leaks quickly and reduce waste. | 30 | 1000 |

| Advanced Control Systems | Utilizing digital tools for better control over gas flow. | 35 | 2500 |

| Staff Training | Training personnel on best practices for operating regulators. | 10 | 1500 |

| System Upgrades | Upgrading to newer, more efficient regulator models. | 40 | 3000 |

Innovative Technologies for Optimizing Regulator Operations

Innovative technologies are revolutionizing the performance of natural gas regulators, ensuring they operate at peak efficiency while enhancing safety and reliability. Advanced monitoring systems, for instance, utilize real-time data analytics to optimize flow rates and detect anomalies. By employing smart sensors, operators can continuously track pressure and temperature fluctuations, allowing for immediate responses to any irregularities. This proactive approach not only minimizes downtime but also reduces the risk of potential hazards associated with gas distribution.

Additionally, machine learning algorithms are being integrated into regulator operations to forecast potential maintenance needs. These predictive analytics tools analyze historical performance data, helping companies to schedule maintenance before issues arise, thereby extending the lifespan of equipment and ensuring uninterrupted service. Furthermore, the adoption of remote control technologies enables operators to manage regulators from centralized locations, streamlining operations and reducing the need for on-site interventions. This innovative integration of technology into the regulatory framework not only optimizes performance but also paves the way for more efficient and sustainable natural gas management.

Importance of Staff Training in Natural Gas Regulation Management

Effective management of natural gas regulators is crucial for ensuring safety, efficiency, and compliance in the industry. One of the most significant factors in optimizing the performance of these systems is the training of personnel. According to a recent report by the American Gas Association, approximately 52% of natural gas incidents are attributed to human error, underscoring the necessity for comprehensive staff training programs. By equipping employees with the knowledge and skills required to operate and maintain gas regulators, companies can significantly reduce the risk of accidents and enhance system performance.

Furthermore, a study by the Gas Technology Institute highlights that operators who undergo regular training are 30% more likely to identify and correct potential issues before they escalate. This proactive approach not only bolsters safety but also leads to improved operational efficiency, resulting in potential cost savings. Industry leaders are increasingly recognizing that investing in continual education for staff is not just a regulatory requirement but a strategic advantage, contributing to the overall effectiveness of gas regulation management.

Related Posts

-

Leading the Global Market with China's Best Gas Pressure Regulator Innovations

-

Innovative Alternatives in High Pressure Gas Regulators for 2025 Technological Advancements

-

5 Essential Tips for Choosing the Best Hydrogen Pressure Regulator

-

How to Choose the Best Gas Regulator Valve for Optimal Safety and Performance in Industrial Applications

-

The Future of Precision Control: Innovations in Flow Regulator Technology

-

How to Optimize Your Systems with Pressure Control Valves for Maximum Efficiency