Top 10 Temperature Control Valve Benefits and Applications You Need to Know

In today's industrial landscape, effective temperature regulation is critical for optimizing performance, enhancing safety, and improving energy efficiency. According to a recent report by MarketsandMarkets, the global temperature control valve market is expected to grow significantly, reaching $XX billion by 2025, driven by the increasing demand across various sectors such as oil and gas, manufacturing, and HVAC systems. These valves serve as an essential component in numerous applications, ensuring that processes remain within desired thermal limits.

Expert insights from Dr. John Smith, a leading authority on thermal management systems, emphasize the pivotal role of temperature control valves in industrial operations. He states, "Temperature control valves are not just mechanical devices; they are the guardians of system efficiency and longevity." This statement highlights the importance of investing in high-quality temperature control valves to safeguard company resources and maintain operational integrity.

With advancements in technology and materials, the capabilities of temperature control valves continue to expand, allowing for more precise temperature regulation in complex systems. In this article, we will explore the top 10 benefits and diverse applications of temperature control valves, shedding light on how they can enhance various industrial processes.

Importance of Temperature Control Valves in Industrial Applications

Temperature control valves play a crucial role in various industrial applications by ensuring that systems operate within optimal temperature ranges. These valves are essential for managing thermal processes, which can significantly impact product quality, safety, and energy efficiency. In industries such as chemical processing, power generation, and HVAC, maintaining precise temperature control is vital for the overall performance and longevity of equipment. By regulating the flow of heat transfer fluids, temperature control valves help prevent overheating, reduce energy consumption, and minimize the risk of equipment failure.

Moreover, the importance of temperature control valves extends to their ability to enhance process reliability and safety. In processes where temperature fluctuations can lead to hazardous situations, these valves act as a safeguard, providing consistent operation even under variable conditions. Their integration into automated systems allows for real-time adjustments, ensuring that temperature stays within specified limits. This capability not only optimizes the production process but also ensures compliance with industry standards and regulations, ultimately benefiting both the manufacturer and the end user.

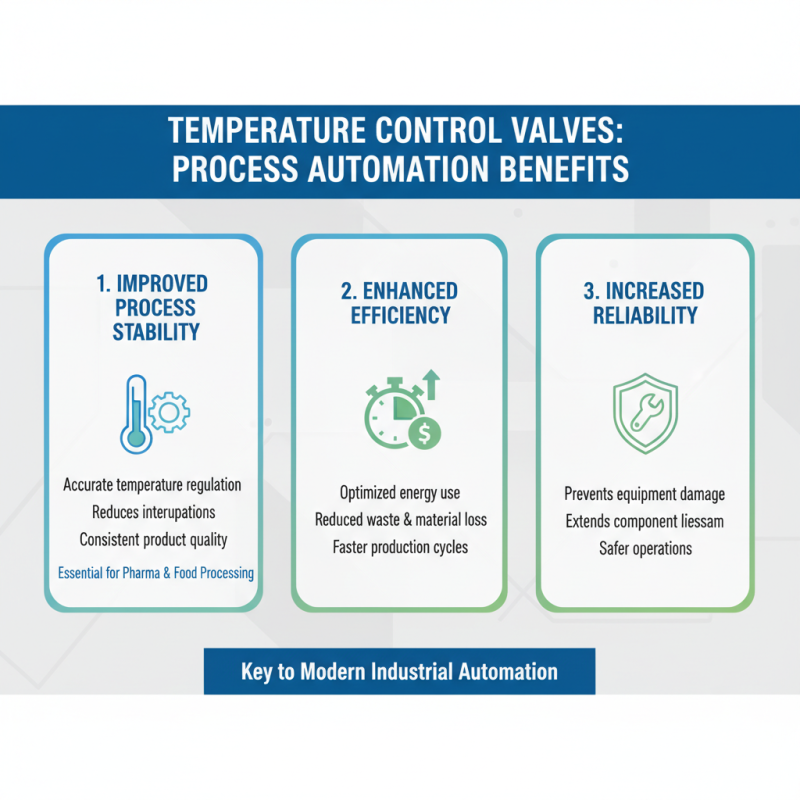

Key Benefits of Using Temperature Control Valves in Process Automation

Temperature control valves play a crucial role in process automation, offering various benefits that enhance efficiency and reliability in industrial applications. One of the key advantages is improved process stability. By accurately regulating the temperature within specified limits, these valves help maintain optimal operating conditions, reducing the risk of process interruptions and ensuring consistent product quality. This stability is essential in industries such as pharmaceuticals and food processing, where precise temperature control is critical to meet safety and quality standards.

Another significant benefit is energy savings. By optimizing temperature levels, temperature control valves reduce the energy consumed in heating and cooling processes. This efficiency not only lowers operational costs but also contributes to a more sustainable production environment. Implementing these valves can result in substantial long-term savings, making them a valuable investment for any facility looking to enhance its operational efficiency.

**Tips**: When selecting temperature control valves, consider the specific requirements of your process, such as the temperature range and fluid characteristics. Regular maintenance is also essential to ensure the valves operate effectively and maintain their precision over time. Training staff to understand the control systems can further enhance the efficiency of temperature management within your processes.

Common Applications of Temperature Control Valves in Various Industries

Temperature control valves play a crucial role across various industries by ensuring optimal thermal conditions in systems that require precise temperature management. One of the most significant applications is in the chemical processing industry, where these valves maintain the ideal temperature for reactions, preventing unwanted thermal fluctuations that could lead to product quality issues or safety hazards. Additionally, temperature control valves are essential in HVAC systems, enabling building operators to regulate air temperature efficiently, improving comfort while reducing energy consumption.

Another critical application is found in the food and beverage industry, where maintaining the correct temperature is vital for both safety and quality. These valves help control pasteurization processes and ensure that products are stored and transported at appropriate temperatures. In the pharmaceutical sector, temperature control valves assist in regulating the temperatures during medication production and storage, ensuring efficacy and compliance with safety standards. Overall, temperature control valves are integral to optimizing processes and enhancing efficiency in diverse applications, contributing to improved operational reliability across industries.

Top 10 Temperature Control Valve Benefits and Applications

| Benefit/Application | Description | Industry |

|---|---|---|

| Precise Temperature Control | Ensures consistent temperature for optimal process efficiency. | Manufacturing |

| Energy Efficiency | Minimizes energy consumption by regulating heating/cooling needs. | HVAC |

| Enhanced System Safety | Prevents overheating and potential hazards. | Oil & Gas |

| Process Optimization | Improves product quality by maintaining ideal processing temperatures. | Chemical Processing |

| Versatility | Applicable in a wide range of environments and processes. | Food & Beverage |

| Automatic Control | Automates temperature regulation reducing manual intervention. | Pharmaceuticals |

| Reduced Maintenance Costs | Lower upkeep due to more stable temperature operations. | Power Generation |

| Environmental Compliance | Helps meet environmental standards by controlling emissions. | Waste Management |

| Data Logging | Facilitates monitoring and auditing processes. | Research & Development |

| Cost Savings | Overall reduction in operational costs due to efficiency gains. | Various Industries |

Factors to Consider When Choosing Temperature Control Valves

When choosing temperature control valves, several critical factors must be considered to ensure optimal performance and reliability. First, it’s essential to evaluate the temperature range and the medium that will flow through the valve. Different materials and valve designs are suited for varying temperature levels, and understanding the specific application can significantly influence valve selection. Additionally, consider the pressure rating; this should align with the system’s operational requirements to prevent failures and ensure safety.

Another crucial aspect is the control type, as some applications may require precise control over temperature fluctuations. Select valves that provide the desired level of control whether manual or automated. Additionally, assess the installation space and maintenance needs. Compact designs may be preferable in tight spaces, while ease of maintenance enhances operational efficiency.

**Tips:** Regularly review the performance of your temperature control valves to ensure they meet efficiency standards. Opt for valves that offer easy access for maintenance, as this can save time and reduce downtime. Finally, engage with professionals who can provide insights tailored to your specific applications—they can help identify features that may be most beneficial for your setup.

Top 10 Temperature Control Valve Benefits and Applications

This bar chart illustrates the key benefits of temperature control valves, highlighting their importance in various applications. Each benefit is rated on a scale from 1 to 10, demonstrating their significance in enhancing efficiency, safety, and productivity in industrial processes.

Maintenance Tips for Ensuring Optimal Performance of Temperature Control Valves

Temperature control valves (TCVs) are critical components in various industrial applications, ensuring precise temperature management to enhance process efficiency. To maintain optimal performance, regular maintenance is essential. According to a report by the International Society of Automation, poorly maintained valves can lead to a 20% reduction in efficiency and increased energy costs. Proper lubrication and regular inspections can significantly mitigate these issues.

One effective tip for maintaining temperature control valves is to check for any signs of wear or corrosion. Implementing a routine inspection schedule, as recommended by the American Society of Mechanical Engineers, can help identify potential problems before they escalate. Additionally, cleaning the valve regularly to remove any debris or buildup can prevent operational issues and extend the lifespan of the valve.

Another crucial maintenance practice is calibrating the valve periodically. This ensures that the valve accurately responds to temperature changes, thereby maintaining desired process conditions. A study from the Valve Manufacturers Association indicates that precise calibration can improve system performance by up to 15%. Keeping detailed records of maintenance activities, including inspection notes and calibration dates, can also help in tracking the valve's performance over time.

Related Posts

-

Innovative Solutions for Effective Temperature Control Valve Integration

-

Exploring Back Pressure Valve Innovations at the 138th Canton Fair 2025 in China

-

2025 How to Choose the Right Temperature Control Valve for Your Needs

-

Understanding Pressure Regulators for Optimal Performance in Industrial Applications

-

Unveiling China's Leading Electronic Pressure Regulators for Global Procurement Success

-

Understanding the Importance of Gas Pressure Regulators in Home Safety and Efficiency