Top 7 Benefits of Using a Pressure Reducer for Optimal Performance

In today's rapidly evolving industrial landscape, optimizing performance and efficiency is crucial for businesses aiming to remain competitive. A key component in achieving these goals is the utilization of pressure reducers. According to a report by the International Energy Agency, implementing pressure regulation systems can lead to energy savings of up to 25%, significantly reducing operational costs for various sectors, including manufacturing and HVAC systems. The benefits of using a pressure reducer extend beyond just energy efficiency; they also play a vital role in maintaining equipment longevity and ensuring safety in operations.

Furthermore, research published in the Journal of Industrial Engineering highlights that pressure reducers can prevent hazardous surges in pressure, which may damage pipes and other infrastructure. This capability not only safeguards physical assets but also mitigates the risk of operational downtime, contributing to enhanced productivity. As industries strive for both sustainability and reliability, understanding the advantages of pressure reducers becomes essential. This article explores the top seven benefits of using pressure reducers, providing valuable insights into how they can lead to optimal performance in various applications.

Benefits of Pressure Reducers in Enhancing System Efficiency and Safety

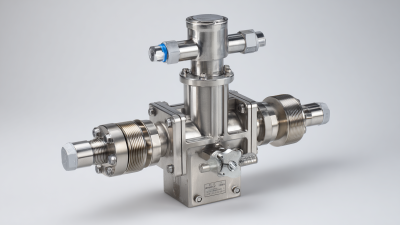

Pressure reducers play a crucial role in enhancing system efficiency and safety across various industries, including energy and manufacturing. By maintaining optimal pressure levels, these devices help improve the performance of systems that operate under high-pressure conditions. According to a report by the International Energy Agency, implementing pressure regulation can lead to a reduction in energy consumption of up to 10%, as it minimizes the energy wasted from leaks and over-pressurization. This not only contributes to lower operational costs but also plays a significant part in achieving sustainability goals.

In addition to improving efficiency, pressure reducers enhance safety by preventing excessive pressure build-up, which can lead to system failures or even hazardous situations. The Occupational Safety and Health Administration highlights that proper pressure management reduces the risk of accidents, such as explosions or equipment damage. Enhanced safety measures are particularly vital in industries utilizing new technologies, such as ammonia as a marine fuel, where effective pressure control can mitigate the risks associated with high-pressure storage and transport.

With the push towards reducing greenhouse gas emissions, ensuring the safe handling of alternative fuels like ammonia is paramount, and pressure reducers will be key in maintaining a balance between operational efficiency and safety.

Minimizing Water Hammer and Pressure Fluctuations with Pressure Reducers

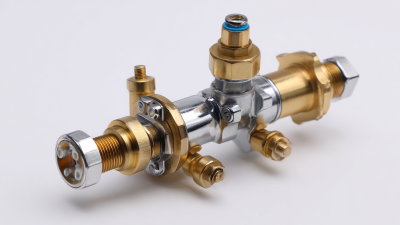

Pressure reducers are essential devices that help maintain stable water pressure in plumbing systems, significantly minimizing issues such as water hammer and pressure fluctuations. Water hammer, a phenomenon caused by sudden changes in water flow, can lead to loud banging noises and potential damage to pipes. By installing a pressure reducer, homeowners can effectively control the water pressure, allowing for smoother water flow and reducing stress on plumbing fixtures.

Moreover, pressure fluctuations can cause inconsistent water delivery, affecting everything from showering comfort to washing machine efficiency. A pressure reducer acts as a buffer, ensuring a consistent and manageable water pressure regardless of fluctuating demands from different outlets in the system. This stability not only enhances overall system performance but also prolongs the lifespan of plumbing components, resulting in long-term savings on repairs and replacements. Through these benefits, pressure reducers contribute to a more efficient and reliable water supply system.

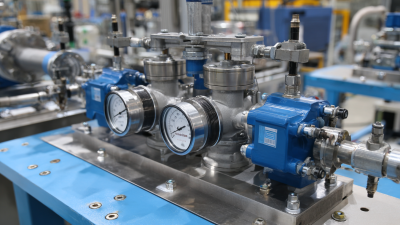

Lower Energy Costs through Improved Pressure Management in Industrial Applications

In industrial applications, efficient pressure management is crucial for optimizing energy consumption and operational performance. Utilizing a pressure reducer can significantly lower energy costs by maintaining the ideal pressure levels required for various processes. When pressure is regulated, equipment operates within optimal limits, reducing wear and tear, which in turn leads to less frequent maintenance and lower replacement costs. The consistent and appropriate pressure provided by reducers ensures that machinery runs efficiently, preventing energy loss associated with overpressure situations.

Moreover, improved pressure management enhances the overall productivity of industrial systems. By reducing excess pressure and ensuring a steady flow, businesses can achieve more precise control over their operations. This results in reduced waste of resources and minimizes the risk of accidents or equipment failures caused by pressure fluctuations. Ultimately, implementing a pressure reducer not only streamlines processes but also contributes to long-term sustainability and cost savings across various industrial applications.

Top 7 Benefits of Using a Pressure Reducer for Optimal Performance

| Benefit | Description | Impact on Energy Costs |

|---|---|---|

| Improved Efficiency | Maintains optimal pressure levels, reducing energy waste. | Up to 20% reduction in energy costs. |

| Extended Equipment Life | Reduces stress on equipment, minimizing wear and tear. | Lower maintenance costs over time. |

| Consistent Performance | Ensures stable pressure, leading to uniform production quality. | Reduced production errors, lower costs associated with rework. |

| Safety Enhancement | Decreases the risk of pressure-related accidents in facilities. | Potential savings on insurance premiums. |

| Reduced Noise Levels | Lower pressure results in less operational noise. | Improved work environment potentially reducing turnover. |

| Environmental Impact | Minimizes energy consumption, leading to a lower carbon footprint. | Possibility of tax benefits or incentives. |

| Cost-Effective Solution | Initial investment balanced by significant long-term savings. | Overall reduction in operating costs. |

Extending Equipment Lifespan by Preventing Overpressure and Related Damage

Using a pressure reducer not only optimizes performance but also significantly extends the lifespan of equipment by preventing overpressure and related damages. Overpressure can lead to mechanical failures, inefficiencies, and hazardous situations, particularly in industries where explosive environments are a concern. By regulating the pressure within systems, pressure reducers safeguard against shock waves and surges that can compromise the integrity of machinery, much like the protective measures now being implemented in military training to mitigate blast injuries from weapon systems.

Moreover, the ongoing research into blast overpressure and its effects on brain health highlights the need for similar protective strategies in various fields. For example, the adoption of pressure reducers parallels the military's effort to assess cognitive impacts and enforce safety guidelines for personnel exposed to high-pressure scenarios. By proactively managing pressure levels, industries can not only protect their equipment but also ensure the well-being of their workforce, ultimately fostering a safer working environment aligned with best practices in risk management.

Ensuring Consistent Water Flow and Quality in Residential and Commercial Settings

In both residential and commercial settings, maintaining consistent water flow and quality is essential for optimal performance. One of the primary benefits of using a pressure reducer lies in its ability to stabilize water pressure, preventing fluctuations that can lead to inefficient operation of appliances and plumbing systems. High water pressure can cause wear and tear on pipes, leading to leaks and costly repairs. By regulating the pressure, homeowners and businesses can ensure that their water systems operate smoothly.

Additionally, pressure reducers contribute to improved water quality. When water is delivered at a consistent pressure, it reduces the likelihood of contaminants entering the system, particularly in plumbing installations with complex configurations. Moreover, steady water pressure enhances the effectiveness of water filtration systems, ensuring that clean, safe water is delivered to taps. This not only protects the infrastructure but also significantly benefits health and hygiene standards, making pressure reducers an invaluable tool for anyone looking to enhance the reliability and quality of their water supply.

Top 7 Benefits of Using a Pressure Reducer for Optimal Performance

Related Posts

-

Common Issues Regarding Back Pressure Regulator Selection and Performance

-

Understanding the Common Issues Faced with Pressure Regulators in Industrial Applications

-

Essential Checklist for Choosing the Right High Pressure Regulator for Your Industrial Needs

-

How to Identify Top Quality Manufacturers for the Best Pressure Regulator

-

Understanding Pressure Regulators for Optimal Performance in Industrial Applications

-

What is a Pressure Reducing Valve and How Does It Ensure System Efficiency