Understanding the Functionality of the Best Back Pressure Valve

In various industrial applications, the significance of back pressure valves cannot be overstated. According to the Global Industrial Valves Market report, the demand for valves, including back pressure valves, is projected to grow at a CAGR of 6.2% from 2021 to 2028, underscoring their critical role in fluid control systems. These valves are essential in maintaining system pressure, ensuring operational efficiency, and preventing potential damage from overpressure scenarios. However, challenges persist in their application, such as suboptimal performance during pressure fluctuations and compatibility issues with different media, which can lead to inefficiencies and increased maintenance costs. This blog will delve into the functionality of the best back pressure valves, exploring their industry applications and addressing common problems associated with this vital component.

The Basics of Back Pressure Valves: Definition and Purpose

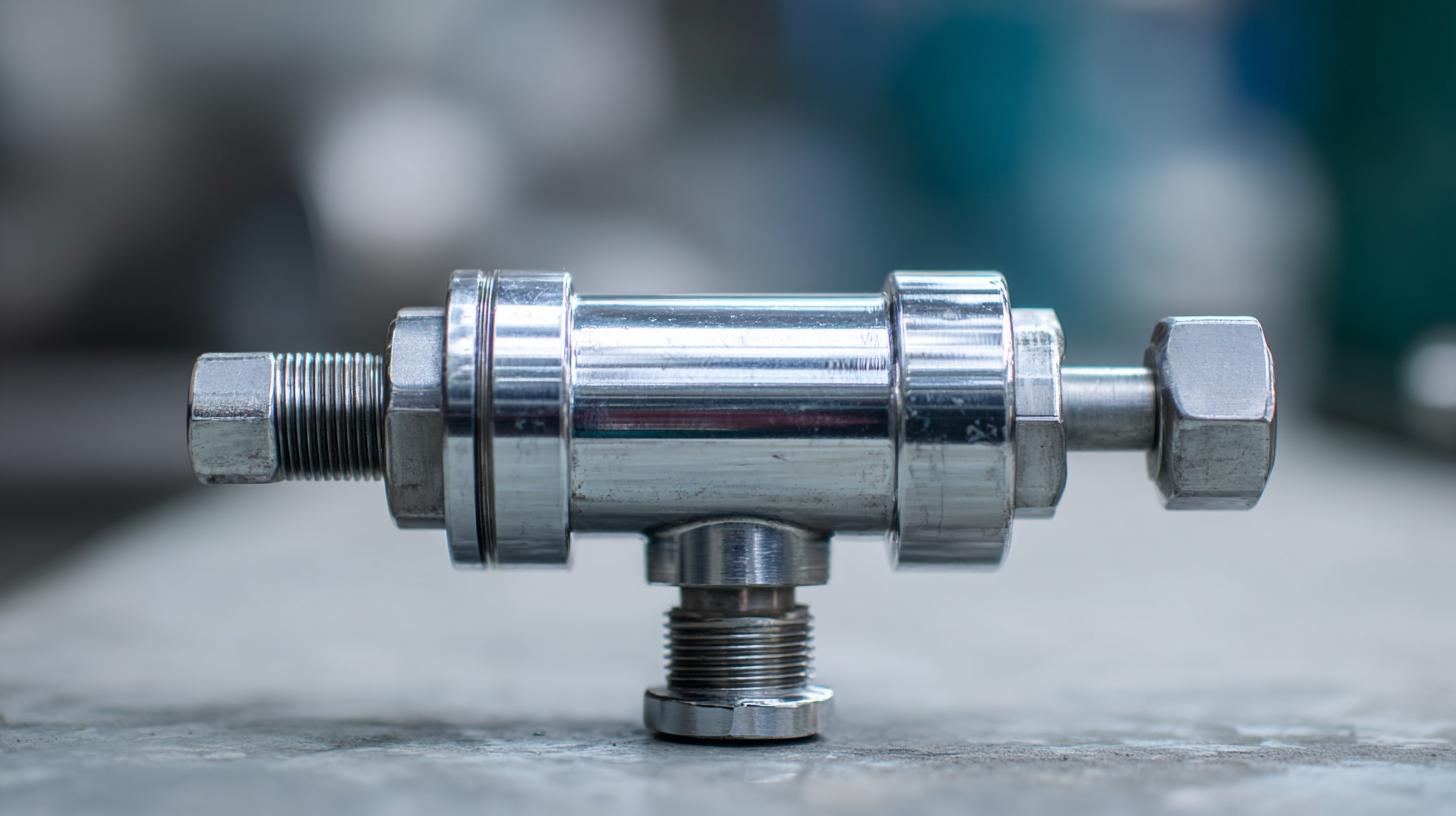

Back pressure valves play a crucial role in managing pressure within a system. These devices are designed to maintain a specific pressure level upstream, preventing backflow and ensuring that processes run smoothly. By allowing fluid to flow in only one direction and holding back excessive pressure, back pressure valves contribute significantly to operational safety and efficiency.

When selecting a back pressure valve, it's essential to consider factors such as the type of media being controlled and the operating pressure requirements. For optimal performance, ensure that the valve's specifications match the system's needs. Regular maintenance is also key, as it can prevent wear and ensure reliable functionality.

**Tip:** Always consult with a professional before installation to ensure compatibility with your system. **Tip:** Keep a maintenance schedule to check the valve’s functionality and prevent potential failures. Incorporating these valves not only enhances system integrity but can also lead to cost savings by avoiding unnecessary breakdowns.

Understanding Back Pressure Valves Functionality

This chart illustrates the functionality of back pressure valves by comparing key performance metrics, including flow rates in both liters per minute (L/min) and gallons per minute (GPM) as well as pressure measurements in both bars and PSI. These metrics are essential in understanding how these valves operate under different conditions.

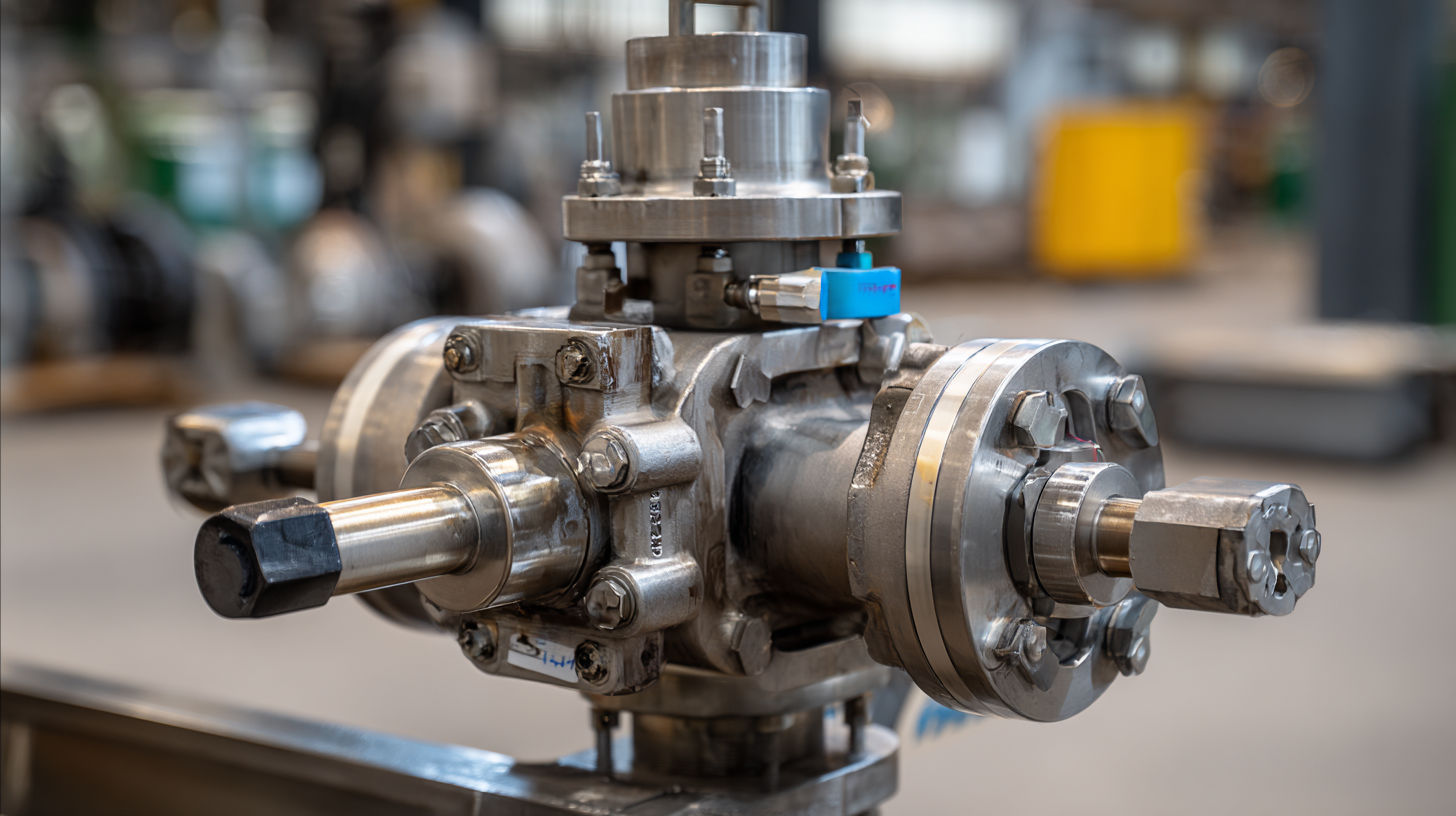

Key Components of Back Pressure Valves and Their Functions

Back pressure valves play a crucial role in managing fluid flow and pressure in various industrial applications. Key components of these valves include the bonnet, disc, and spring. The bonnet houses the internal components and provides a secure seal, while the disc acts as the primary modulating element to control flow. The spring ensures that the disc remains in the closed position until the preset pressure threshold is surpassed, thus allowing for self-regulation of back pressure. The effectiveness of these valves is highlighted in studies showing that as back pressure increases, the flow rate experiences a gradual decline—a critical factor for maintaining system stability.

Recent advancements in mechatronic systems have further enhanced the functionality of back pressure valves, particularly in contexts necessitating precise flow control, such as in chemical analytical systems. Research indicates that with the integration of hydrogel-based technologies, these valves can now respond dynamically to environmental stimuli, offering improved performance in lab-on-a-chip applications. The potential of these systems is significant, as they facilitate real-time monitoring and adjustment of flow rates, ensuring optimal operation within closed-loop configurations. The effective implementation of these technologies can lead to more efficient and reliable processes across various industries.

How to Choose the Right Back Pressure Valve for Your System

When selecting the right back pressure valve for your system, it’s essential to understand the distinct functionalities these devices offer. Back pressure valves regulate the upstream pressure in a piping system, ensuring that the process flows correctly and efficiently. According to industry reports, an appropriately selected back pressure valve can enhance system reliability by up to 30%, minimizing operational disruptions.

The choice of back pressure valve should consider several factors, including the expected flow rates, pressure range, and the specific application it is designed for. Recent advancements in valve technology have led to greater precision and efficiency in operation. For instance, automated systems provide real-time monitoring of valve performance, enabling operators to make data-driven decisions that can boost productivity by at least 20%. By evaluating these metrics and matching them with the operational needs of your facility, you can select a back pressure valve that not only meets regulatory standards but also optimizes system performance and longevity.

Common Applications and Use Cases for Back Pressure Valves

Back pressure valves are critical components in various industrial applications, ensuring optimal system performance and protection. They are commonly employed in processes such as wastewater management, oil and gas operations, and chemical production. In wastewater systems, these valves help maintain consistent pressure, preventing backflow that could lead to contamination. In the oil and gas industry, they are instrumental in controlling pressure levels in pipelines, safeguarding equipment from potential damage due to pressure surges.

When integrating back pressure valves into your system, consider the specific needs of your application. **Tip:** Always select a valve that matches the pressure ratings and flow characteristics of your system to enhance efficiency. Regular maintenance is also crucial; ensuring that valves are free from debris can prevent malfunction and prolong their lifespan.

Additionally, back pressure valves can be utilized in various chemical processes to maintain pressure in reactors. This not only improves safety but also optimizes reaction conditions. **Tip:** Monitor the operating conditions closely to adjust the valve settings for peak performance. By understanding the versatility and functionality of back pressure valves, industries can leverage these tools to enhance operational efficiency and safety dramatically.

Understanding the Functionality of the Best Back Pressure Valve - Common Applications and Use Cases for Back Pressure Valves

| Application | Industry | Functionality | Benefits |

|---|---|---|---|

| Process Control | Chemical Manufacturing | Maintains desired pressure levels | Increases safety and efficiency |

| Fluid Regulation | Oil & Gas | Controls the flow rate of fluids | Prevents system overload |

| Back Pressure Maintenance | Water Treatment | Maintains pressure upstream of the valve | Enhances operational stability |

| Leak Prevention | Pharmaceuticals | Minimizes the risk of leaks and contamination | Increases product quality |

| Energy Recovery | Power Generation | Recovers energy from pressure fluctuations | Reduces operational costs |

Maintenance Tips for Ensuring Optimal Performance of Back Pressure Valves

Back pressure valves play a crucial role in maintaining optimal system performance by regulating pressure and preventing backflow. To ensure these valves operate effectively, regular maintenance is essential. Start with routine inspections, checking for any signs of wear, corrosion, or mechanical failure. Pay special attention to the seals, as they are often the first components to degrade, leading to leaks that can compromise system integrity.

Cleaning is another vital aspect of maintenance. Accumulated debris can obstruct the valve's functionality, leading to inaccurate pressure readings and inefficient operations. Use appropriate cleaning agents that won’t damage the valve materials, and ensure all components are thoroughly rinsed and dried before reassembly. Additionally, lubrication should be applied to moving parts to reduce friction and enhance longevity.

Lastly, keep an eye on the calibration of the valves. Over time, pressure settings may drift, affecting performance. Regular calibration checks can help maintain correct operational parameters, ensuring that the back pressure valve responds adequately to changing system demands. By adhering to these maintenance tips, you can considerably extend the lifespan and efficiency of your back pressure valves.